Advantages for the same are as follows:

- Plan vs Actual can be easily checked and verified.

- It helps to reduce the Rework.

- Options for each BOM is ready with the operator and can be checked also with the help of Tool.

Implementation:

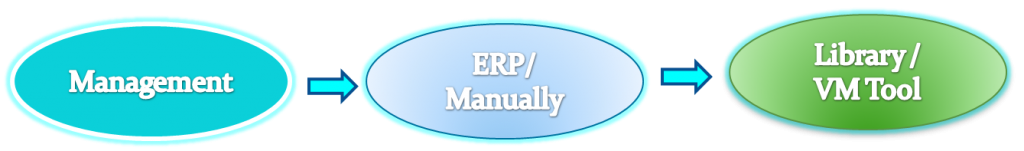

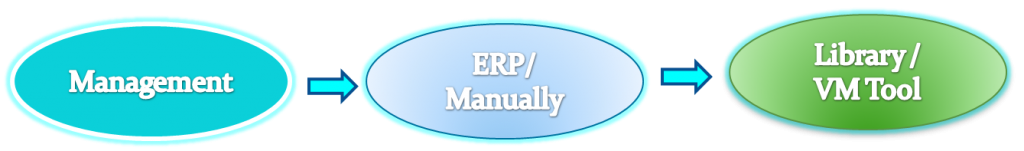

Firstly the data is saved in the ‘Library’ , which is build during development. It consist of the specification as per the design of the product. The Library fetches the data either through ERP or manually prepared reports. Library can save upto 5000 metrics.

This is how PLAN reaches the Software(Library).

There are various steps in implementation of VMS . The steps are as follows:

- Order in a sequence

- Appropriate Information to concerned Individual

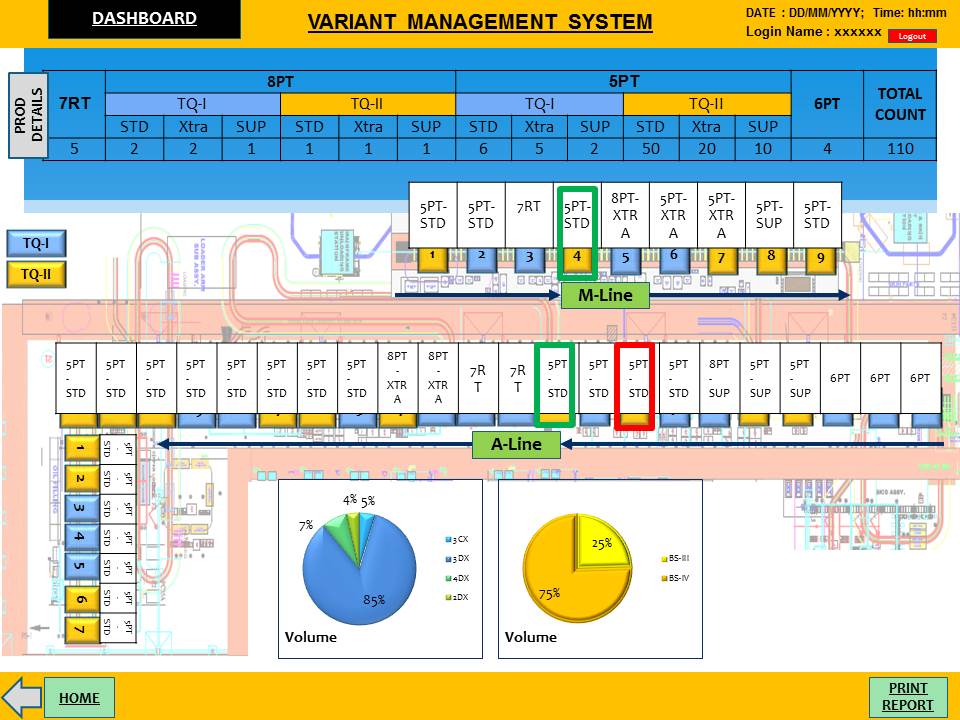

- Comparing Plan v/s Actual

- When the Production Plan is prepared , the information is fed to ERP. The same Is fetched in Library, which is build during development of VM Tool.

- When the component comes on assembly line , the signal is transmitted to VM Tool , the matrics related to the product comes on the screen,if it qualifies then marked as OK. Plan vs Actual is checked.

- The barcode is placed on each component of the machine which is scanned and matched with the pre defined specification. ( present in the Library).

- The RFID tag is placed on each fixture which carries the unique identifier is related to the machine.

- Component assembly takes place on one assembly line and engine assembly takes place on another assembly line. Further, both the components are combined to form a final desired product, which is on each stage qualified with Plan v/s Actual.

ROI

The benefit Variant Management system is to stop the Rework procedure which was time and cost consuming. Generally , customization can no longer be transferred to the customer , therefore, the impetus of these losses comes on manufacturer.