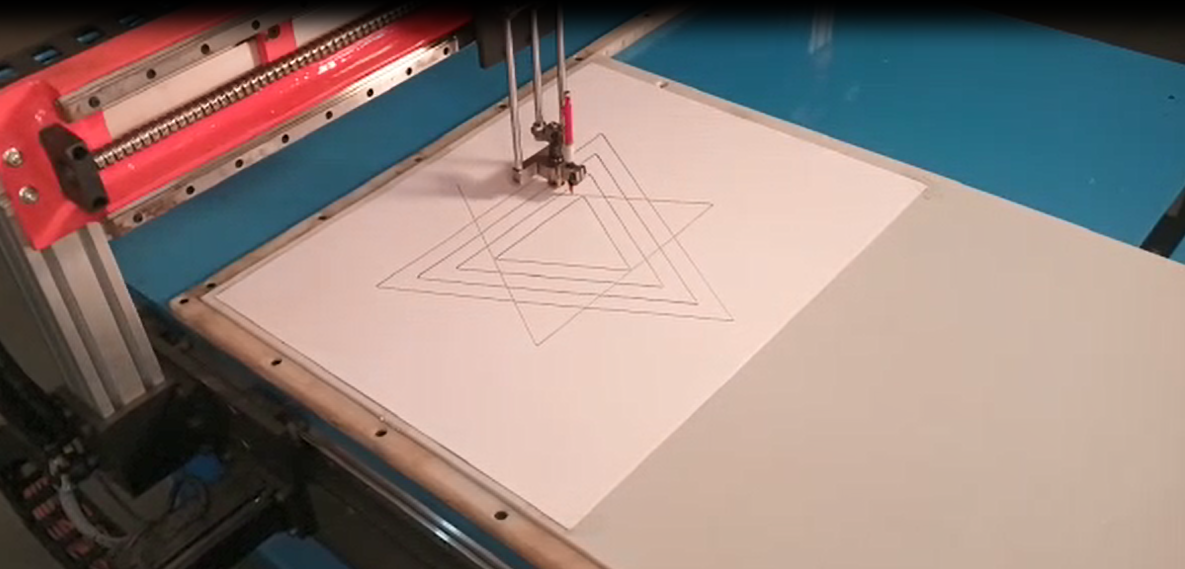

CNC X-Y Axis Machine

Computer numerical control (CNC) is the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands. This is in contrast to machines that are manually controlled by hand wheels or levers, or mechanically automated by cams alone.

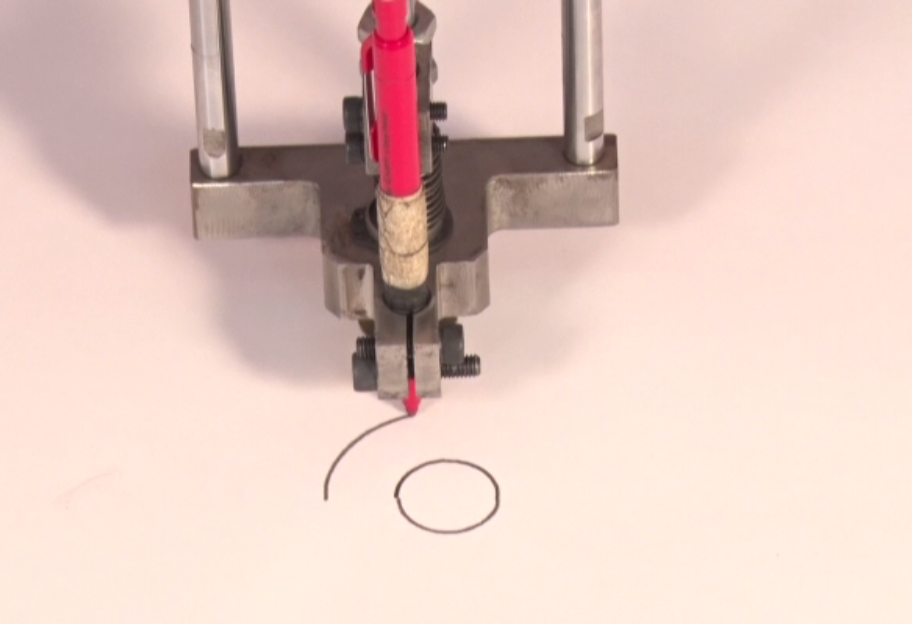

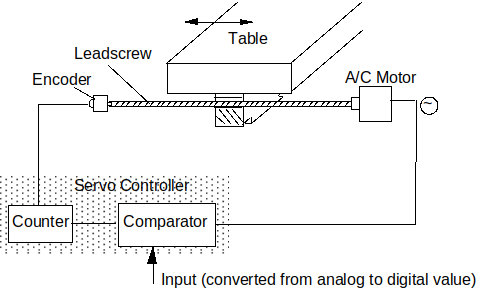

A CNC Machine takes the commanded position from the CNC programme. The drive motor is rotated a corresponding amount, which in turn drives the ball-screw, causing linear motion of the axis. A feedback device confirms that the proper amount of ball-screw revolutions have occurred.

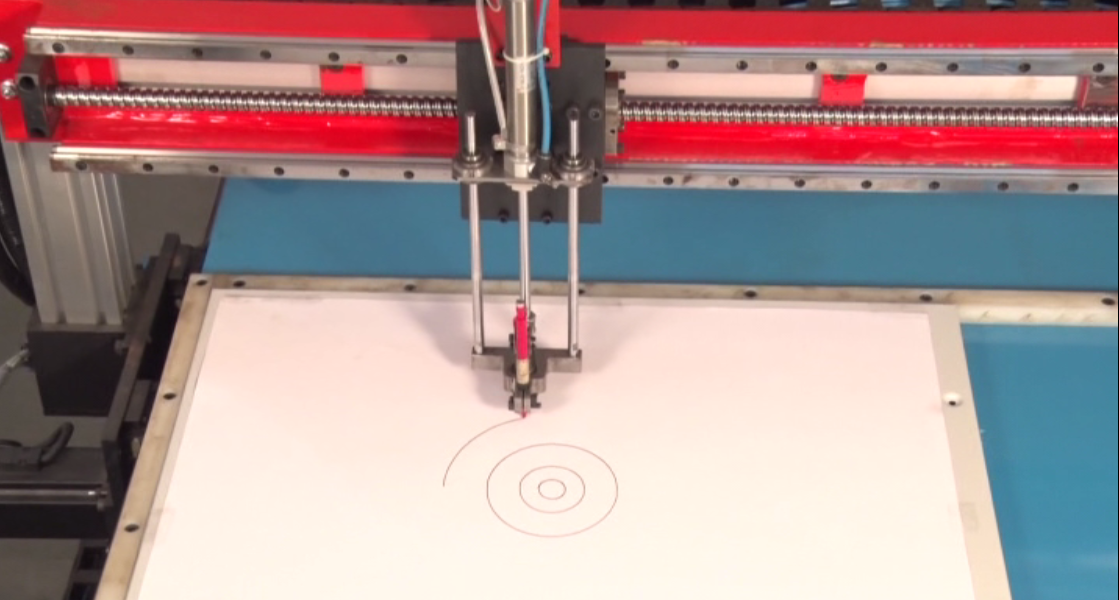

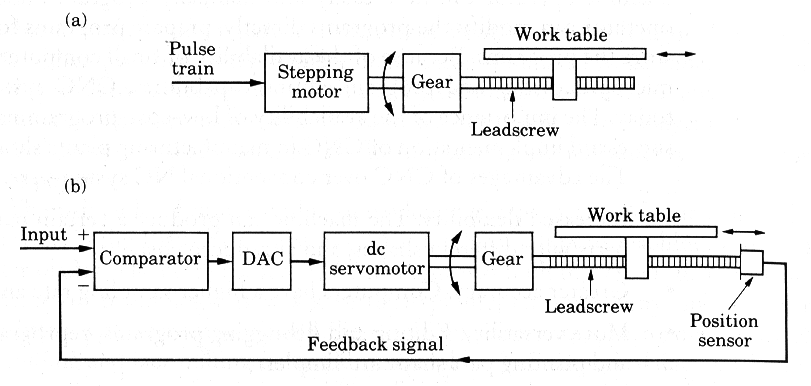

Motion is controlled along multiple axes, normally at least two (X and Y), and a tool spindle that moves in the Z (depth). The position of the tool is driven by direct-drive stepper motor or servo motors in order to provide highly accurate movements, or in older designs, motors through a series of step-down gears. Open-loop control works as long as the forces are kept small enough and speeds are not too great. On commercial metalworking machines, closed loop controls are standard and required in order to provide the accuracy, speed, and repeat-ability demanded.

Motion control is done by: servo-controlled motors |

Open Loop vs. Closed Loop controls |

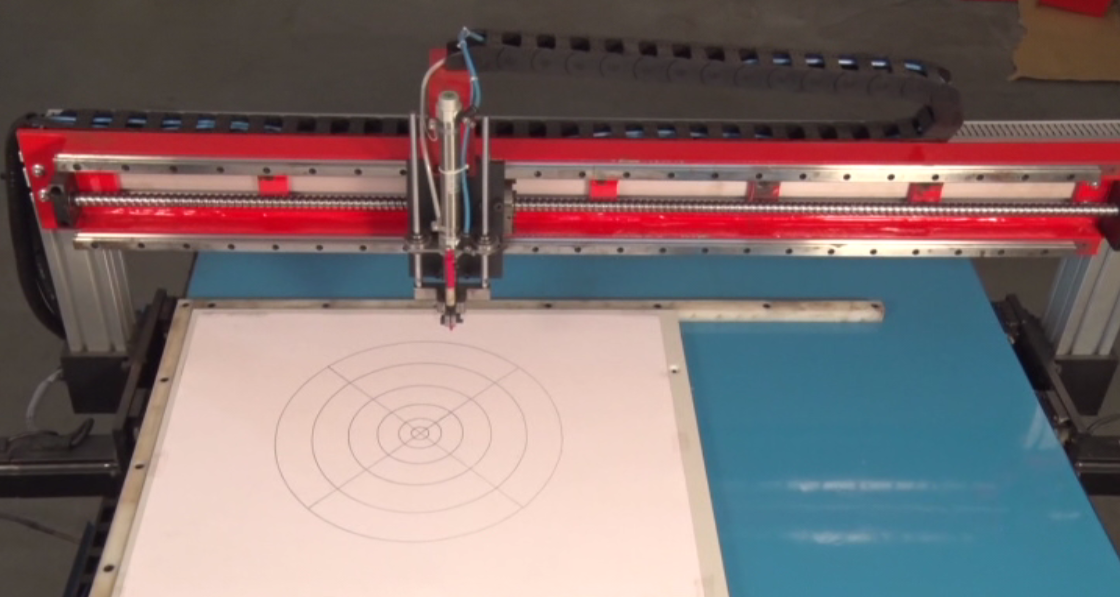

CNC X-Y TABLE Designed, Developed and Manufactured by Reckers Mechatronics

- CNC controlled axes 2200 mm x 1250mm for drawings.

- Table made with MS fabrication.

- X – axis on ball screw and LM guideways

- Y-axis on rack and pinion and LM guideways.

- Speed upto 8000mm/min.

- Directly reads drawing in DXF format from a pen drive and work accordingly.

- Z axis can be added if application so requires.