INDUSTRIAL INTERNET OF THINGS(IIOT)

Controlling & Monitoring Industrial Automation anywhere

Why IIOT?

We are service provider for IIOT in North India . The IIOT is also known as the Industrial Internet of Things. It brings together amazing machines, advanced analytics and people at work. It is a network of many industrial tools connected by communication technologies, which become systems that can monitor, collect, exchange, analyze and disseminate valuable new insights like never before. Following this information can help industrial companies make smarter, faster business decisions.

As with other areas of your business, see where your needs are in reality. Where is your pain If it is in throughput, see how you can use your data in the OEE / FIS app, which gives you a better understanding of the constraints, starvation stations, and machine performance. If you’re adding value to defective products or running a product recalls, consider where you can implement IIOT for traceability. If you have unacceptably high scrap rates, look for IIOT options for error proofing. Another way to look at this is in the context of your most expensive activities. What data are they producing?

FEW OF OUR DELIVERED IIOT SOLUTION

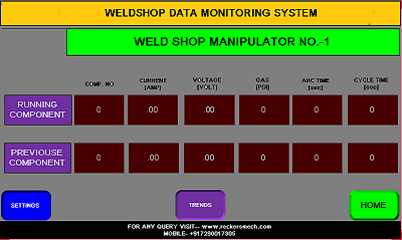

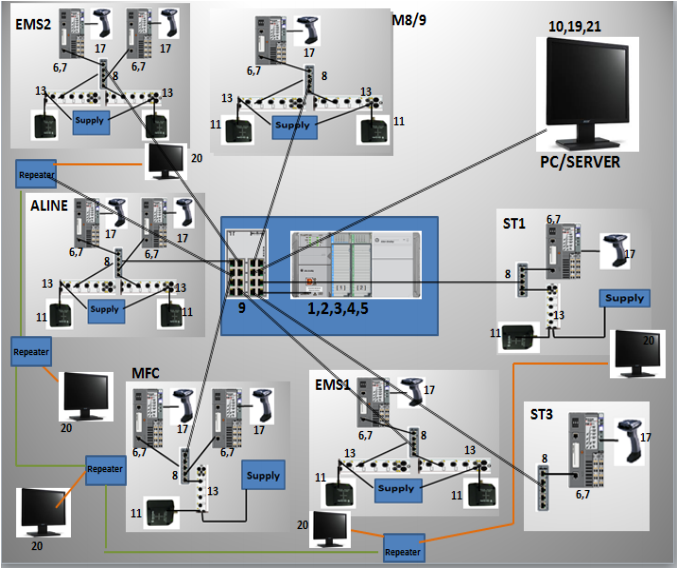

Weld Shop Digitization

Collection of field data from Non-intelligent device without modification in existing system.

learn more

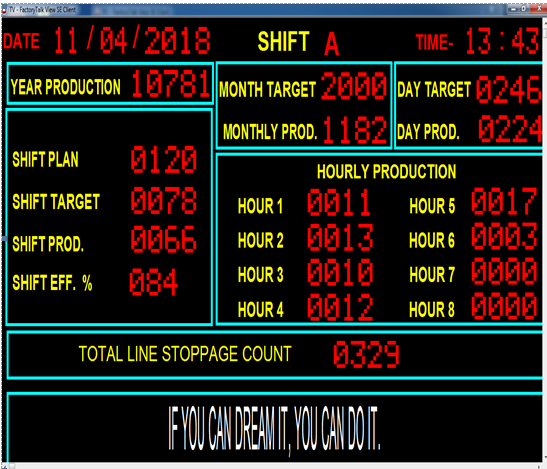

Pre Paint/Post Paint Shop Digitization

Planned Vs Reality DATA GRID required. Monitoring on Central Monitoring System

learn morePaint Shop Digitization

For the whole paint shop there was no centralized control but the centralize Data was required.

learn more

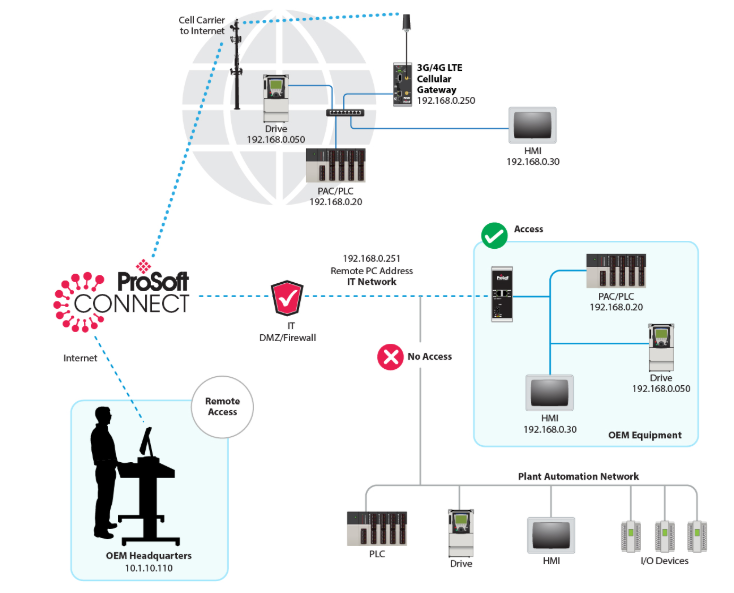

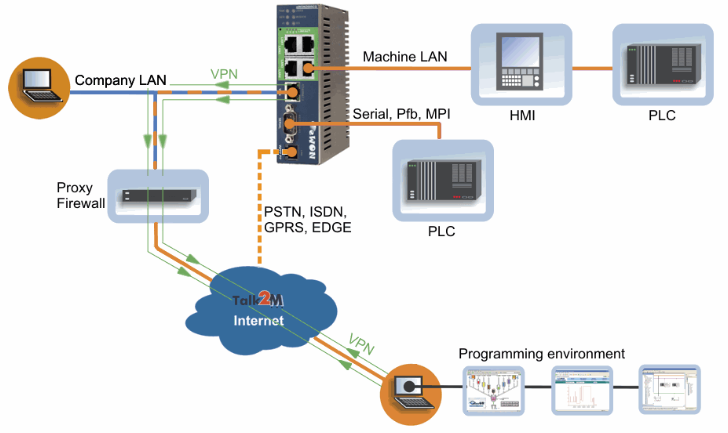

Press Machine Remote Access

Remote Access was required with IT permission with 2 layer protection.

learn moreVARIANT MANAGEMENT

Management of different child parts for the correct parent part without Human Error.

learn more

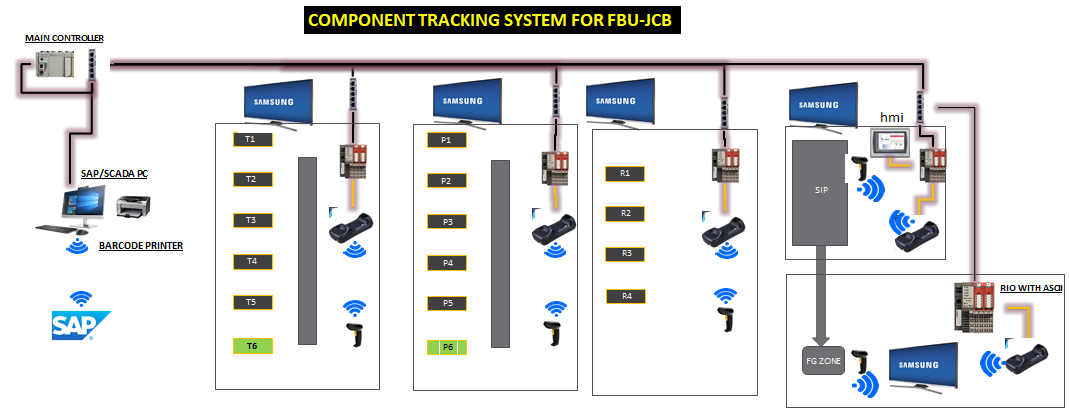

COMPONENT TRACKING

Tracking, ageing, OEE calculation for non-intelligent Frame Assembly Unit.

learn moreIIOT Solution

Smartly connected assets and devices for the overall performance and data monitoring.

learn more

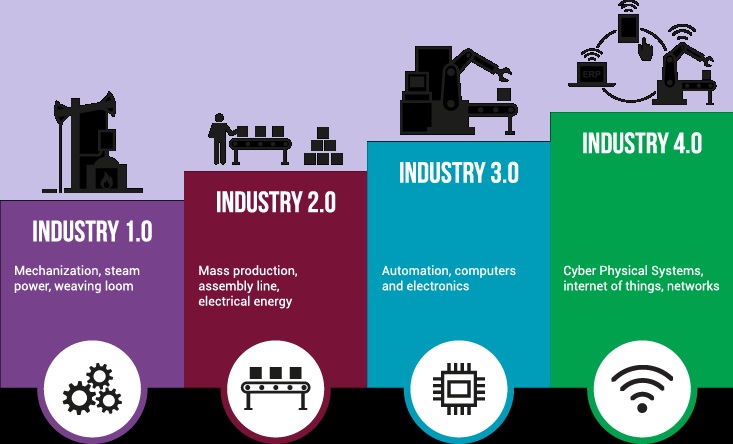

Evolution Of IIOT

1990- Internet of Content.

- Entertainment

- Skype

- Web2.0

- Machine to machine talk

- Identification

- Tracking

- Monitoring

- Things management

- Data management

- access

2000- Internet of services/people Skype

2010- Internet of Things

Core Industry Problems and Our Developments

- Engineers spend too much time for extracting and aligning data from various resources.

- Different tools/software requires for different data.

- Different users are required for different tools.

- Lack of Visibility to Real Time performance against business matrices.

- Predicting and detecting issues and opportunities.

- Making right decision at the right time with the right information.

- Production efficiency

- Process Reliability

- To run the plant at peak performance.

- Eliminate unplanned shutdown.

- Intelligent Safety Solution.

- Remote access of machines with secure access.

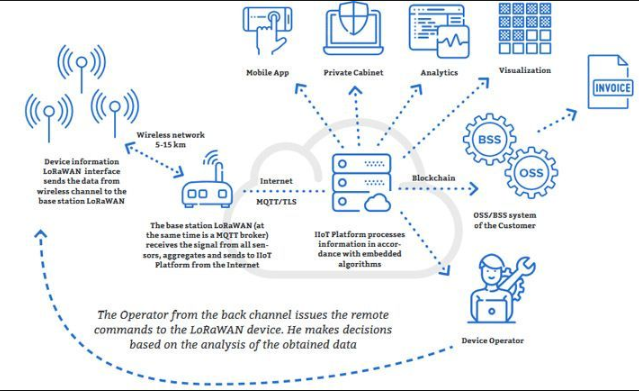

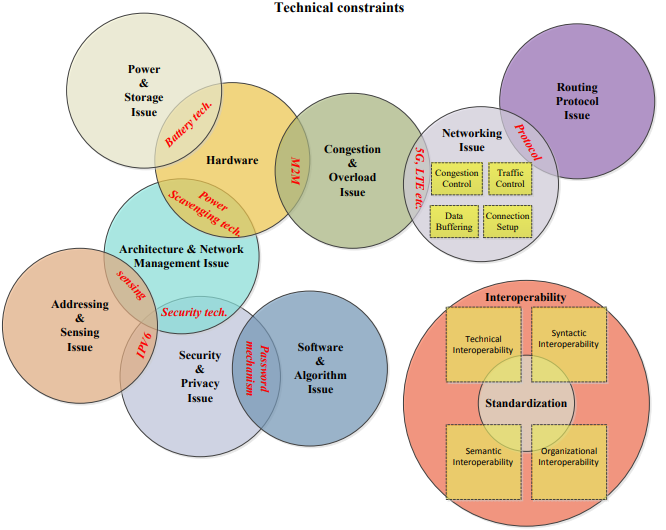

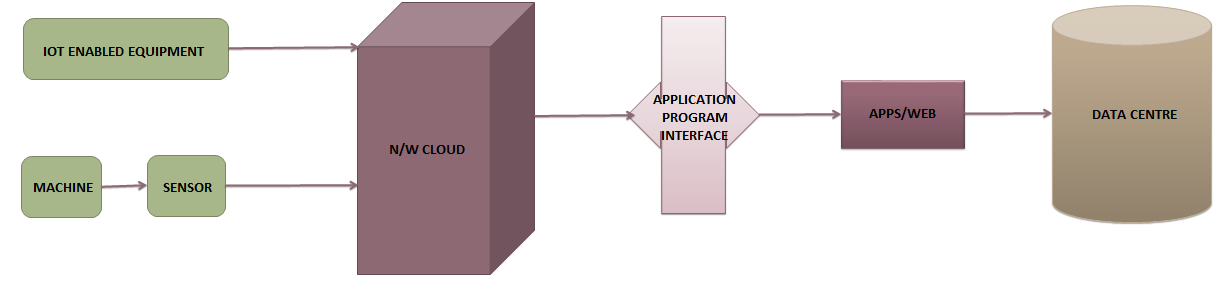

IIOT Architecture

IIOT Vision

In that sense it is safe to say that, despite the fact that we’ve been talking about the Internet of Things for a long time and the fact that IIOT in many industries is a reality, we are still in the early years. Although it is expected that, as a term and concept, the Internet of Things will disappear and just become part of a new normal, we are far from there. Note, however, that in a business context it’s best to focus on goals and use cases when trying to get projects accepted and done than to speak about the IIOT. We are IIOT Service provider in North India.

With the exponential growth, enabled by what Gartner would call a “nexus of forces”, comes growth in many other areas such as traffic, storage, processing capacity, data volumes, network capabilities, you name it.

The Internet of Things exists in many industries, applications and contexts. Some projects are still in the pilot stage while others form the backbone of important processes, operations and innovations. In other words: the Internet of Things is certainly here but the degree in which it is changing the ways we live, work and conduct business depends on the context.

LOOKING AN ADEQUATE SOLUTION FOR YOUR COMPANY?