Traceability

Traceability is the process of maintaining records of all the materials and individual parts from raw material to a finished product where a UID helps to identify a part, a batch or a finished good. In manufacturing process, the activity of collecting and managing information is known as traceability. The information is collected right from the acceptance of a raw material to shipment of that product.

We provide Automotive Industry Solutions. The solutions are provided for the following lines say Production, Inventory, Vendor etc.

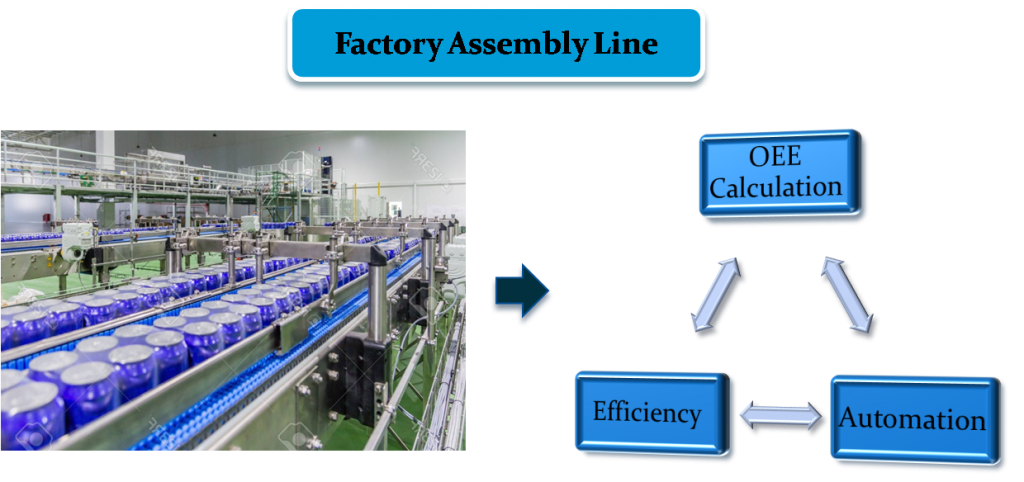

Let’s take an example of Production line. On a assembly line, there are various parameters which are calculated:

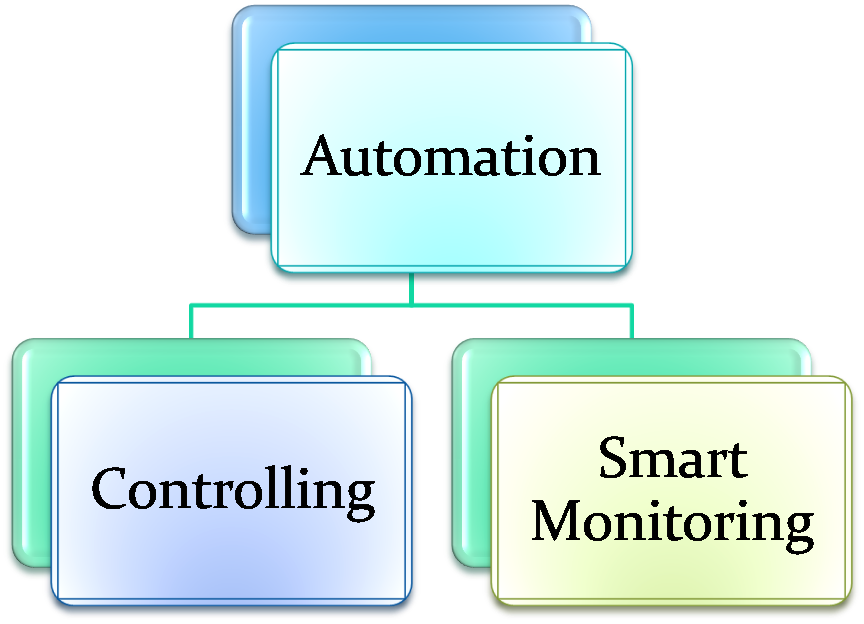

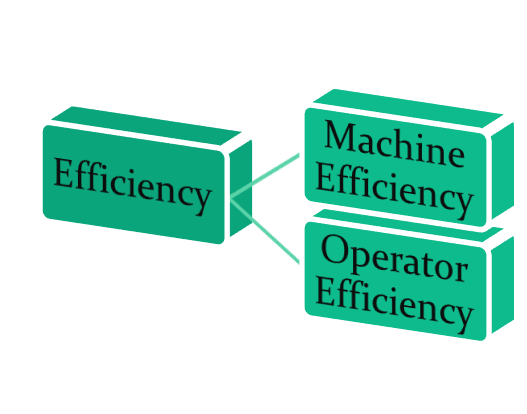

From the above parameters Efficiency and Automation is further divided as:

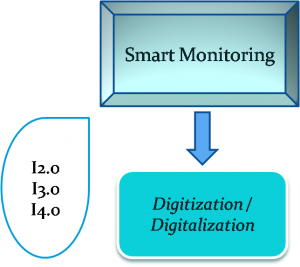

Here by smart monitoring we refer to making the data digital through digitization or digitalization. When we convert the data from reports to computer, it is said digitization. When we convert the data from hardware such as push buttons to HMI , it is called digitalization.

Whether it is digitization or digitalization , it depends upon the ground level equipment available on the assembly line. Now a days the digitization process is done with the help of Industry 4.0.

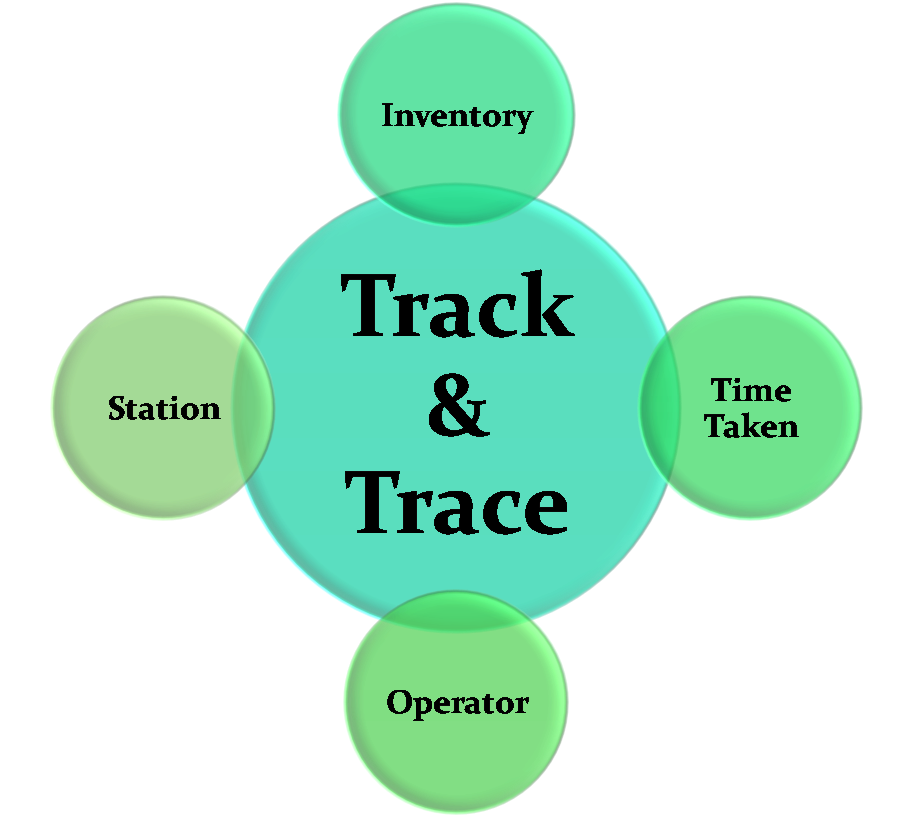

In the production line , when we talk about a particular section, there are different factors on which production depends, these are:

1. Material available

2. Operator Efficiency

3. Record Maintenance

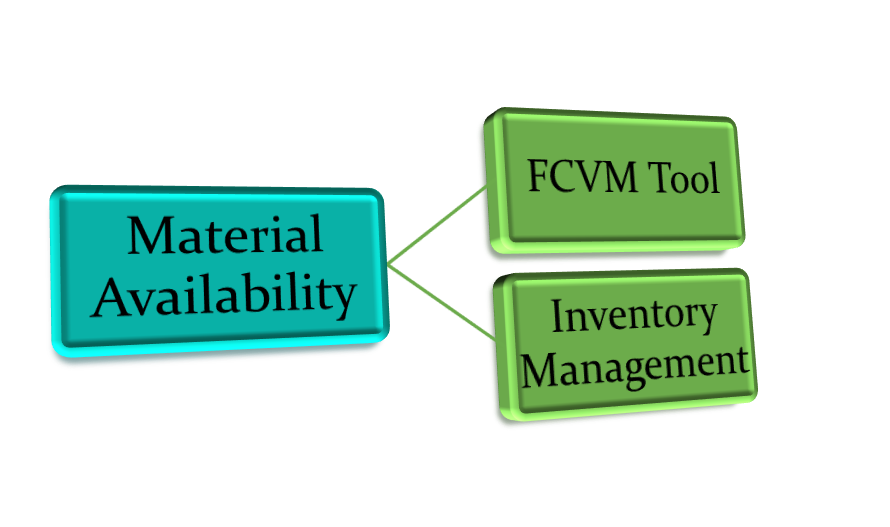

1. Material Availability

We have developed a software , named , VM Tool which takes the input data through ERP or manually in its Library. This Variant Management Tool is also helpful in Inventory Management of the plant.

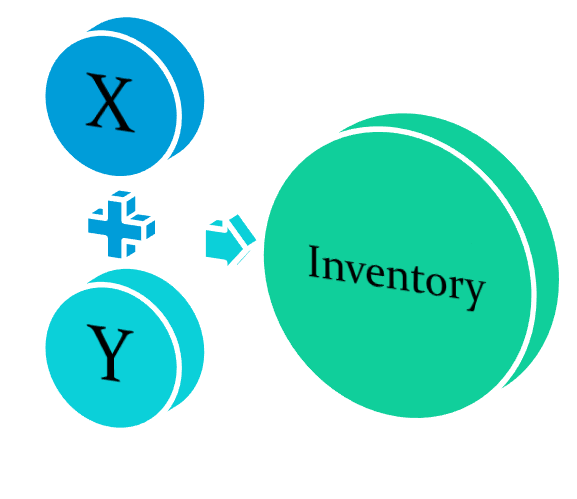

Say, we had raw material , x

Now , after production the raw material left is y

Thus,

2. Operator Efficiency

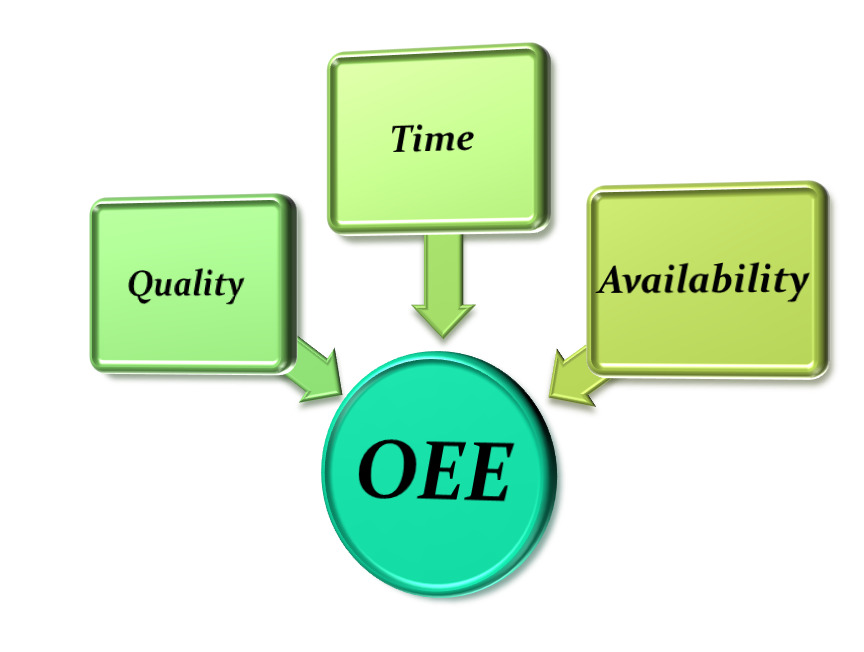

Operator Efficiency is calculated through different factors, like OEE/ANDON & Efficiency. OEE is defined as addition of following factors:

3. Record Maintenance

Reporting is done in various ways:

Thus, tracing can also be known as tracing in the internal system. Every product is marked with UID, and thus when a product is traced back , one can track the raw material of the product and this is called genealogy.