Solution to Big Losses of Manufacturing Industry :OEE

What is OEE?

OEE is basically the metric for benchmarking progress, improving effectiveness, improving the productivity and identifying losses. It is calculated as :

OEE= Availability x Performance x Quality

There are six big losses which occur in manufacturing units while production. It is considered that OEE is used to minimize those losses. The major losses are:

-

Availability Loss

a. Unplanned Stops

b. Planned Stops

-

Performance Loss

a. Small Steps

b. Reduced Speed

-

Quality Loss

a. Production Rejects

b. Startup Rejects

How to Improve Production Losses?

OEE basically aids to increase the efficiency and effectiveness of the manufacturing system. By OEE we can take the reporting in a manner that no manual intervention is there and the system is calculating the real time report of manufacturing.

By OEE we can calculate the performance of individual alongwith availability of raw material.

In Brief:

- OEE helps in reducing the cost of quality manufacturing in a stipulated time.

- It increases the effectiveness of the production.

- Production rate also gets improved.

How OEE works?

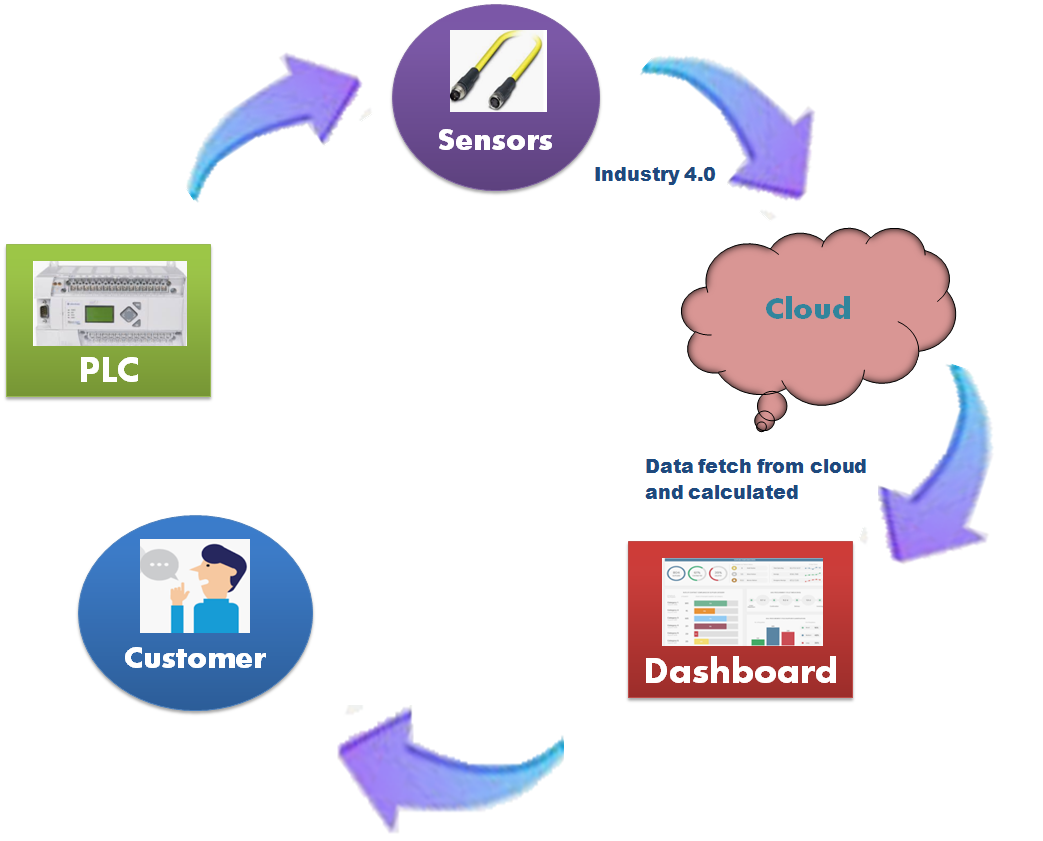

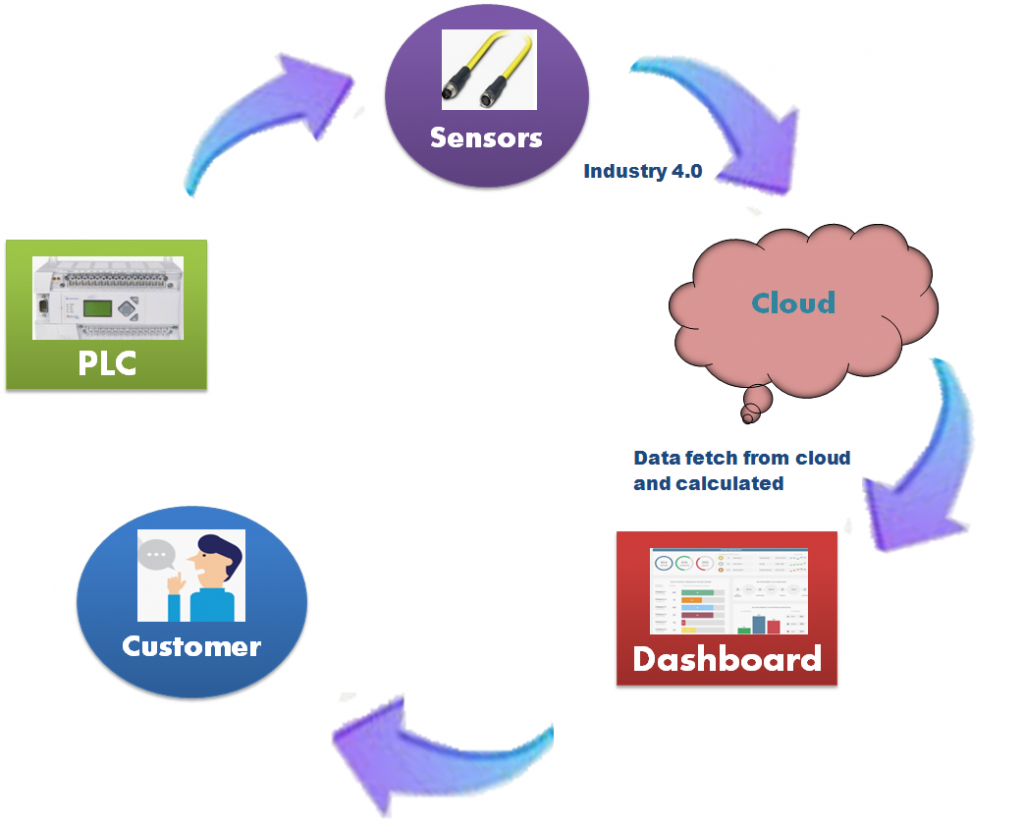

Sensors are placed on the machinery and they measure the relevant parameters such as temperature, pressure etc while the production line is working.

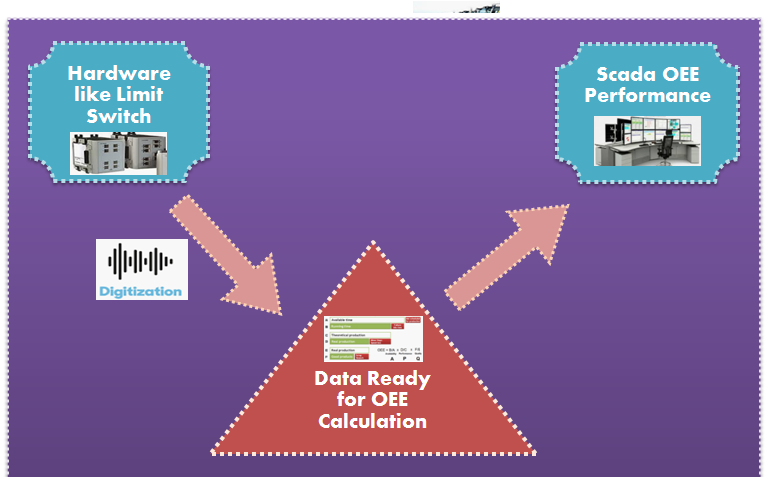

There are two ways:

-

Benefits:

OEE is useful when it helps to take the better decisions regarding how and when production line should progress.

The concerned person can check the relevant data at any given point of time and take the decision as per the same.

Direct Analysis:

The data reaches the concerned person without manipulation and in the format as desired. No more heavy files to access for analyzing the data.