PAINTSHOP DIGITIZATION

CHALLENGE

- For the whole paint shop there was no centralized control but the centralize data was required.

- Performance of each sub-system is required by remote access with very less wiring.

- The challenge was to setup networking of existing system to new system. Communication between Shotblast, Pretreatment, Powder Booth Radiation, Convection Zone SCADA.

- Analysis of whole Paint Shop with critical Parameters was required, visualization of real time operation of plant is to be shown in SCADA, report of each carrier has to be considered.

SOLUTION

- The project is based on Digitization of existing system, thus Ethernet/ IP protocol is provided for the complete PaintShop.

- Since the complete system is interconnected over same platform, a control window is used to operate each individual section like Shotblast, Pretreatment, Radiation, Convection also single start and stop button for Paintshop.

- Secure Gateway has been provided for the remote access operation.

- Wireless control also provided for the Centralize Data Monitoring System.

- Access of critical machinery has been provided from Mobile App for the uninterrupted plant operation.

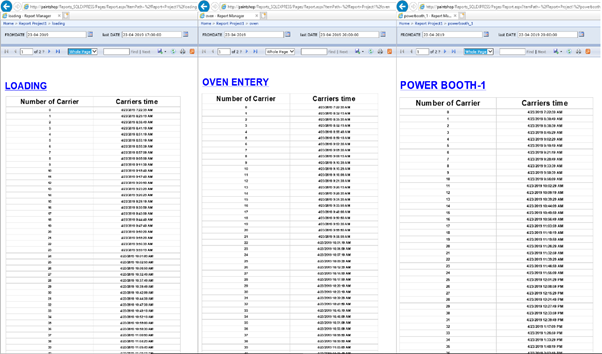

- Carrier data of conveyor is given in form of report.

- Scada system is generating an alert in the form of SMS of all the motors at runtime and breakdown of machines.

- Architecture of all plant is available on single screen, also input output detail is shown in SCADA at real time.

Here below are features of Digitization:

IMPLEMENTATION

We have updated the PLC from SLC to the latest PLC with their existing logic and panel. The logic is being converted from previous PLC to new PLC.

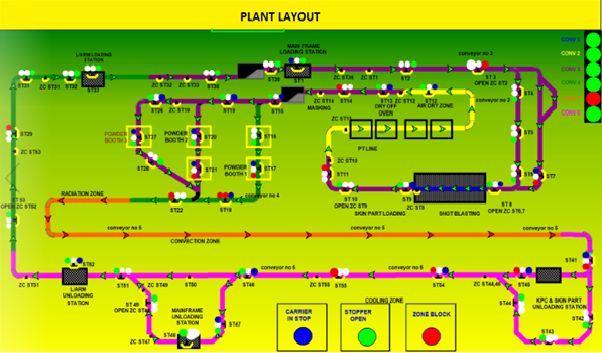

Customer can see all sections of paint shop at one place i.e single SCADA screen is being created for all the sections such as shotblast section, pre-treatment, radiation, convection, conveyor.

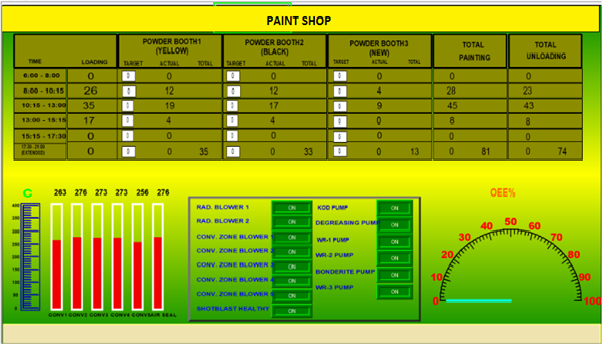

Each detail of production, like how many products got painted, of which color, in which shift it got painted etc, all the details can be observed in single SCADA screen.

All the sections are centralized, all the logic has been uploaded through single control station. SCADA is also provided at remote place through Ethernet.

Here below are few of the SCADA Screens for the ready reference:

PLANT LAYOUT

MAIN DASHBOARD

REPORTING

RESULT

The PLC is upgraded to the latest version with advance features and now the system is easy for operation, visualization and maintenance.