PICK AND PLACE

The pick-and-place application involves both basic maintenance – placing individual product pieces in a tray or carton and packing a case. Progress in building materials, controlling software and hardware, vision systems and other elements have made robots an alternative to different types of pick-and-place. The robot type is best suited for a given pick-and-place application, depending on the required speed, payload size, and other factors. For most applications, only one type of robot is suitable. There are many cross-border applications that can use more than one type and the end user (or his / her system integrator) must prioritize the factors.

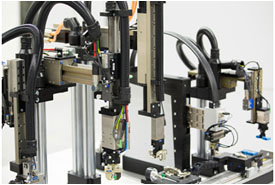

Another improvement is the refinement of motion control software and hardware. The essence of motion control robotics. It is necessary to find objects, take them into the hands of the robot and free them and coordinate up and down with the equipment.

Earlier, robot operation used to require integration between the robot’s motion controllers and programmable logic controllers (PLCs), which coordinated the robot’s actions on the rest of the assembly line. But the tendency is to combine those functions with as many regular controllers as possible. This software eliminates the coding required for the integration of individual controllers.

A variety of robots can be used for upstream pick-and-place:

- Delta-style robots that operate overhead with three or four long, slender arms meet at the ejector head;

- SCARA (Selective Analog Pronunciation Robot Arm) models are fixed base robots with three vertical-axis (horizontal-motion) rotary arms; and

- The multi-axis articulated robot, which has six axes, joints that can rotate in any direction.

As with most aspects of packaging, end-users want pick-and-place to run as fast as possible. But there are practical limitations to some applications. Baked goods such as brittle products need to be handled slowly, which means slowing down.

Pick-and-place applications are fertile ground for robotic devices. As technology and other developments make such devices more viable, end users who choose the right machine will find themselves in a better place.