PALLETIZING AND DE-PALLETIZING USING MULTIPLE AXIS GANTRY

Palletizing products either at the end of the manufacturing i.e final output or at an intermediate location i.e end of a line. Process can be Palletizing or de –palletizing i.e from a pallet product is needed to be put at a conveyor for a process. In simpler words PICK AND PLACE APPLICATIONS.

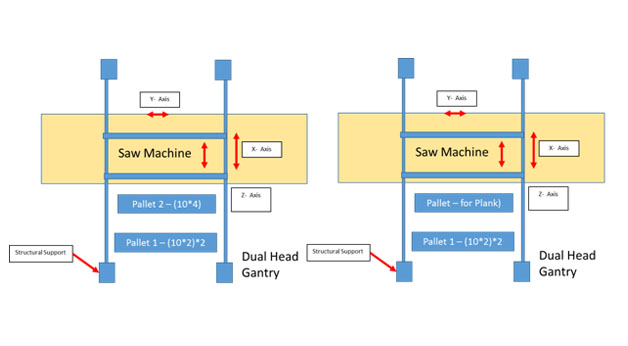

Example 1:

Operational Sequence

- Gantry Robot 1 will pick the part using suitable gripper and will place the part in to the shearing machine.

- Once shearing operation is over the Gantry Robot 2 will pick the sheared part with a suitable gripper and will place the 02 parts onto the pallet 2 and the operation will continue till the pallet will be empty.

- The last part detection will be provided on the gantry robot to generate the alarm that pallet is empty to replace it with filled pallet.

- On pallet replacement the operator will close the safety fence and will acknowledge the automation to start the operation.

Example 2:

Operational Sequence

- Gantry Robot will pick the part using suitable gripper from pallet 2 and will place the part in to the sawing machine.

- Once sawing operation is over the same gantry will pick the parts with a suitable gripper and will place the 02 parts onto the pallet 1 and the operation will continue till the pallet 2 is empty.

- The last part detection will be provided on the gantry robot to generate the alarm that pallet is empty to replace it with filled pallet.

- On pallet replacement the operator will close the safety fence and will acknowledge the automation to start the operation.

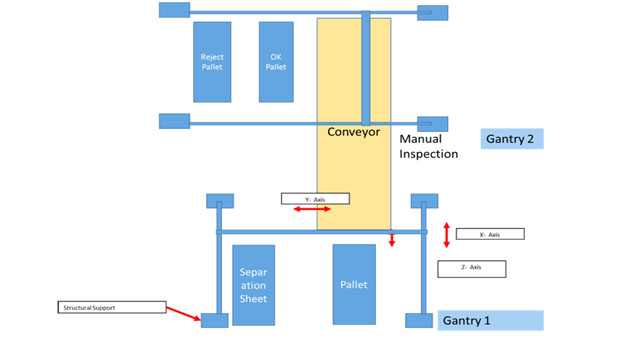

Example 3:

Operational Sequence

- Auto Claved pallet will be placed manually on the designated location.

- Gantry 1 will pick the part and will place onto the conveyor, where the part of the conveyor will be dedicated for the operator for the visual inspection. On inspection operator will press the ok or reject button provided on the conveyor.

- While operator will be inspecting the gantry 1 will pick the separator and will place on the separation pallet

- On press of the decision button the part will be transported to the unloading position on to the conveyor.

- Gantry 2 will unload the part from conveyor and will place on to the ok or reject pallet.

- While making this concept we have considered the separator is of type sheet (new design) and assumed no broken part will come from the autoclave on pallet.