Vision

To implement a machine vision application successfully, a developer needs to know precisely what it needs to achieve. That makes it essential to understand the characteristics of the parts and sub-assemblies which the vision system will examine, as well as the specifications of the production line itself. The key characteristics include: ·

- KW Load

- Specific part dimensions

- Part tolerances

- Needed level of measurement precision

- Minimum size of defects to be detected

- Speed of the production line

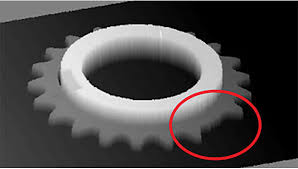

With a comparatively modest investment in machine vision, a major European automobile maker has solved a critical quality challenge in its gear assembly bearings. Before installing the vision system on the production line, the company found it nearly impossible to ensure 100% accuracy—an especially thorny problem because of the safety implications. The machine vision system has now remedied the situation by automatically verifying the presence of all bearings in each assembly and gaging their diameters to make certain they are correctly shaped and undamaged. The company is also taking advantage of the vision system’s “point & click” simplicity with a customized interface that makes it easy for operators to use the system correctly with a minimum of training. Other companies around the world are similarly using machine vision for engine and power train applications such as: ·

- Gaging nozzle holes on oil jet pumps

- Inspecting adhesives applied to gear boxes

- Verifying the presence and correct shape of gear teeth

- Reading characters on engine blocks with OCR functions

- Detecting defective seals on engine blocks

- Inspecting engine castings for defects

- Checking and identifying engine block types before assembly

- Gaging the gaps on spark plugs

- Verifying the presence of critical stoppers on fuel injection pumps