Integration of HPDC Machines for OEE

The project was based on Industry 4.0.

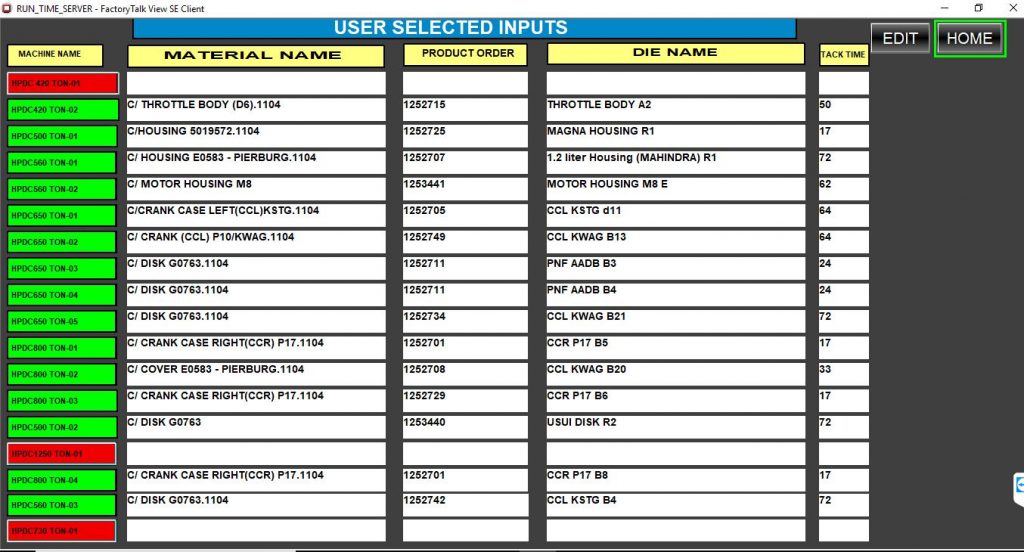

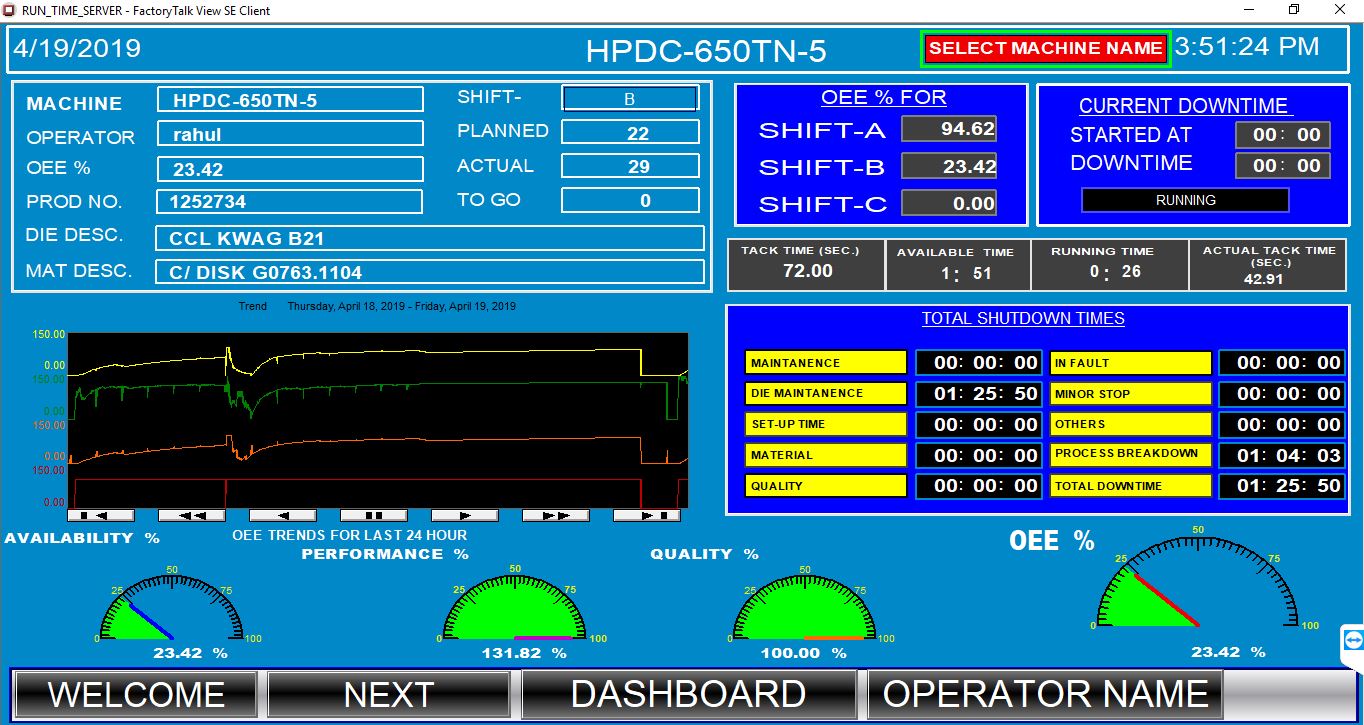

The challenge is to make machine talkative so that it uses its best tools to facilitate us with its best performance for which it is designed off. Also to present the raw data in the manner where anyone ca select the desired inputs which are coming after several data filters created as per the requirement from the customer for a machine.

From the previous Client data (through SAP) which they are using to prepare recipes for the product to be developed on machine and to automate these recipes where machine itself speaks about its best possible tools in terms of DIE, MATERIALS, OPERATOR ETC. Industry 4.0 (IIoT) network is used.

The previous system was running manually where production and downtime or breakdown data is recorded manually for analysis of the product and the system.

To remove this hassle from the system where everything is on pen and paper and also to diminish human intervention into the system. A system has been developed by us which is compatible to their previous system. A system which can talk to the machines with the data given by client. A system which is so handy to use so that anyone can use it without any hassle.

During the first phase of this project we had integrated SAP data into our designed system.

Brief about the system designed by us

On each machine there is a separate data concentrator (Controller or PLC) which is recording Production and breakdown or downtime of machine. Production is recorded with the help of signals and feedback given by client.

For recording downtime or breakdown data a push button box is provided on each machine which contains push buttons with LED. These buttons are customizable as per the customer choice also these are the possible buttons for a machine to be in downtime or breakdown either because of System or Machine fault. For every fault an email and sms is generated by the system to the concern persons.All the data is logging into the SQL for optimization and analysis.

A led will glow till the machine is in breakdown and will off after the machine is in production.

Two parallel SCADA has been designed over which anyone from operator to manager level can view the machine performance. A SAP SCADA communication interface has been developed where authorized persons can select the latest data if generated by SAP in CSV format.

All data has been shared in the CSV format after a certain time frame.

Wow, thanks for sharing, I have learned so much here on your site, thought I’d let you know your efforts are appreciated

I just added this feed to my bookmarks. I really like reading your posts. Thanks!

Application Integration services in Malaysia

thank you so much for appreciating.