Upgradation of Schuler Press in Automation

Challenge: Schuler Hydraulic Press was available with customer ,we had to provide electrical solution and automate the same.

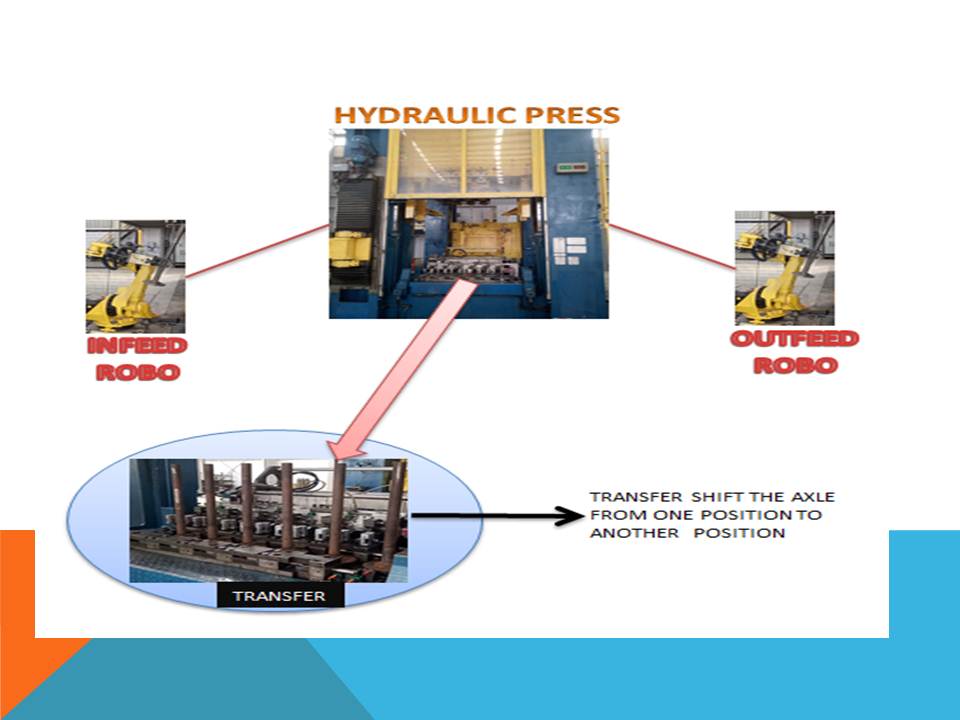

Solution: Since machine was available with customer and we had to automate the same. We provided Electrical Panel and automated / synced the data with the Robot.

Working: This Hydraulic Press Machine works under the pressure of maximum 350 tons and 600 mm/s speed. Press and speed are variable according to customer command in HMI. This machine auto picks up the piece ( say axle) and exit the same with the help of other robot.

Both the Robot communicate with PLC ( Rockwell’s Compact Logix) at Ethernet / IP Protocol. The output is 4 piece in one cycle.

First Robot auto picks the piece (say axle) and puts on transfer 1 , the time is synchronized in a way that it does not collide with other piece. Hydraulic press comes on transfer 1 , a step is formed with increase in height , then it is shifted to transfer 2 and the process repeats till last transfer and is then automatically picked by output Robot.

This process is done by cold extrusion. Earlier this process was done by Hot extrusion. Cold Extrusion is better than hot extrusion the product is of high strength , step is formed by hydraulic press i.e no machining required from third party. And there is no material wastage.