Digital Transformation : Technological Revolution in Manufacturing Industry

Digital transformation has brought a new era of technological revolution in the manufacturing industry. Digital transformation helps in utilizing data of every activity of manufacturing process.

Digital transformation impacts all the process from raw material to finished goods. It helps in making the process systematic and helps in generating a revenue.

Benefits of Digital Transformation

There are tremendous benefits of Digital transformation, brief is as follows:

-

Quality:

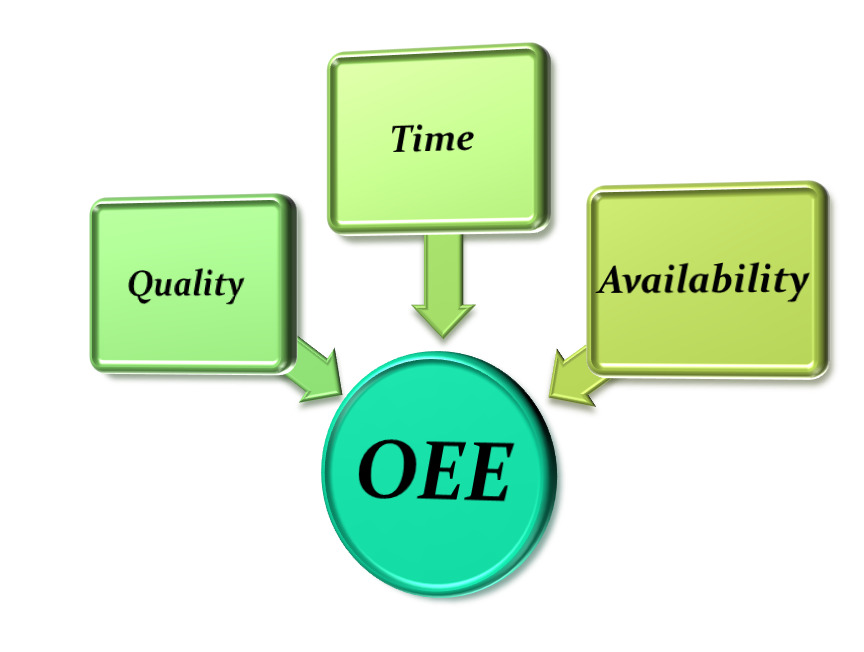

Machine learning algorithms are applied in the process of production from where production process data is generated. This helps in predicting the defects in the production line, also it helps to predict the root cause of defects if any.

Thus, it helps in maintaining the quality in production line as well as it helps to save a lot of time which can be used for productive process.

-

Cost:

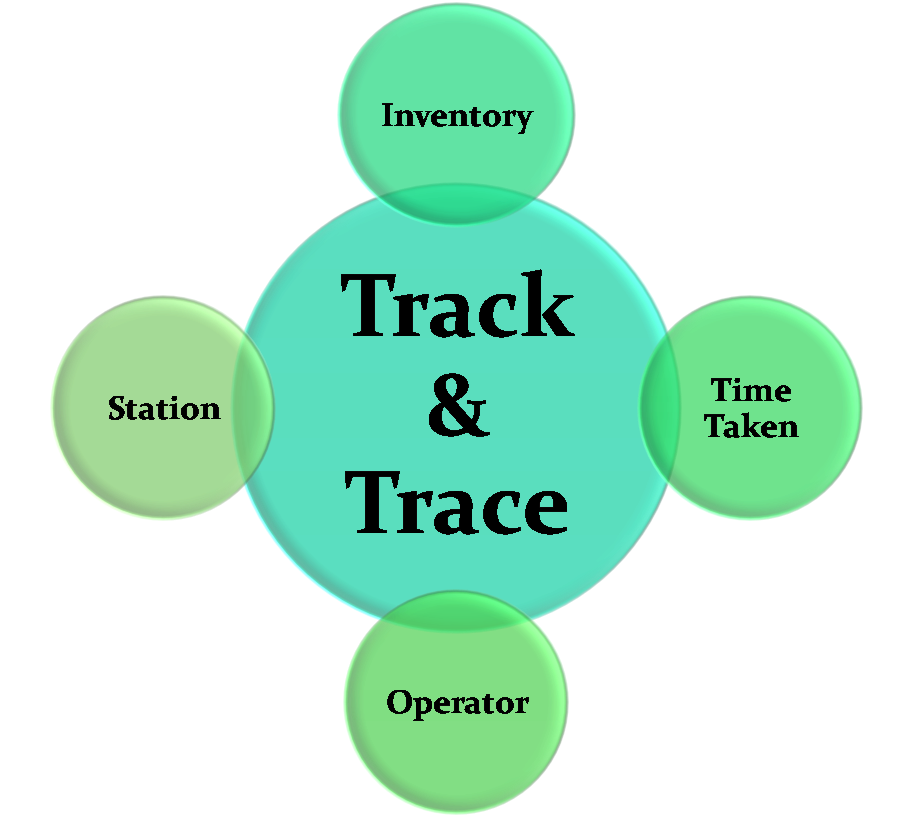

Capturing and analyzing data at all points of the manufacturing line which includes production line and manufacturing data. Analyzing data helps to identify new cost saving opportunities.

Inventory management can be done with the help of IIOT. Inventory management helps to further reduce the wastage in the industry which indirectly impacts the cost of production.Safety & Security

-

Safety & Security:

For digital transformation sensors are to be placed at different points of a process to analyse the data which can intimate in advance of any irregularity.

-

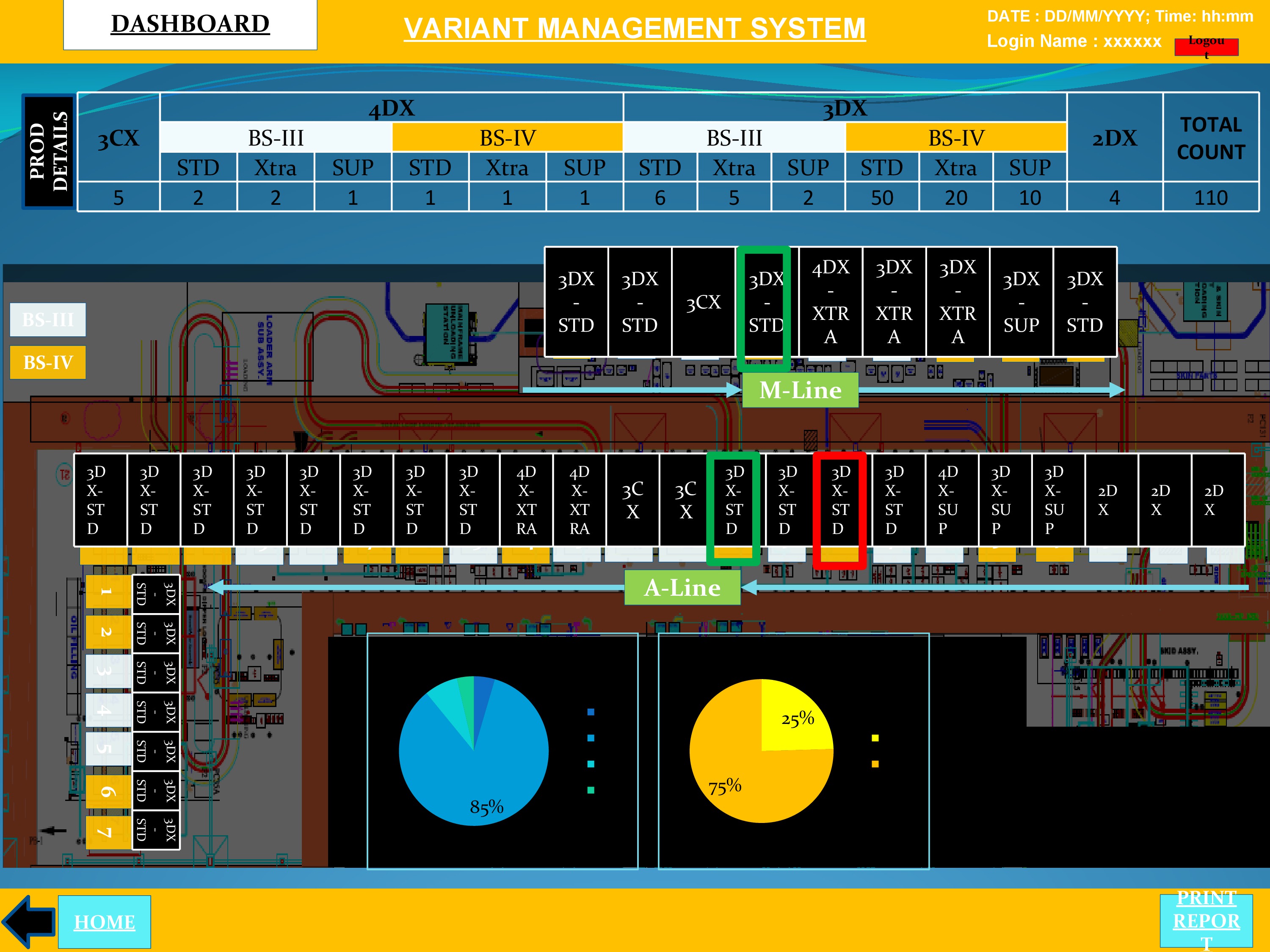

Customization:

Nowadays customization is a key to unlock the requirements of customers. It can be easily achieved with digital transformation. With digitization manufacturing lines can offer a wide customization options to customers while remaining competitive in price.

-

Productivity:

Analysing of data helps in better and faster processes. Since real time data is available with the help of IIOT which further is used for reducing the downtime and increasing the production rate.

Pre information of data is helpful for preventing malfunction in the production line.

-

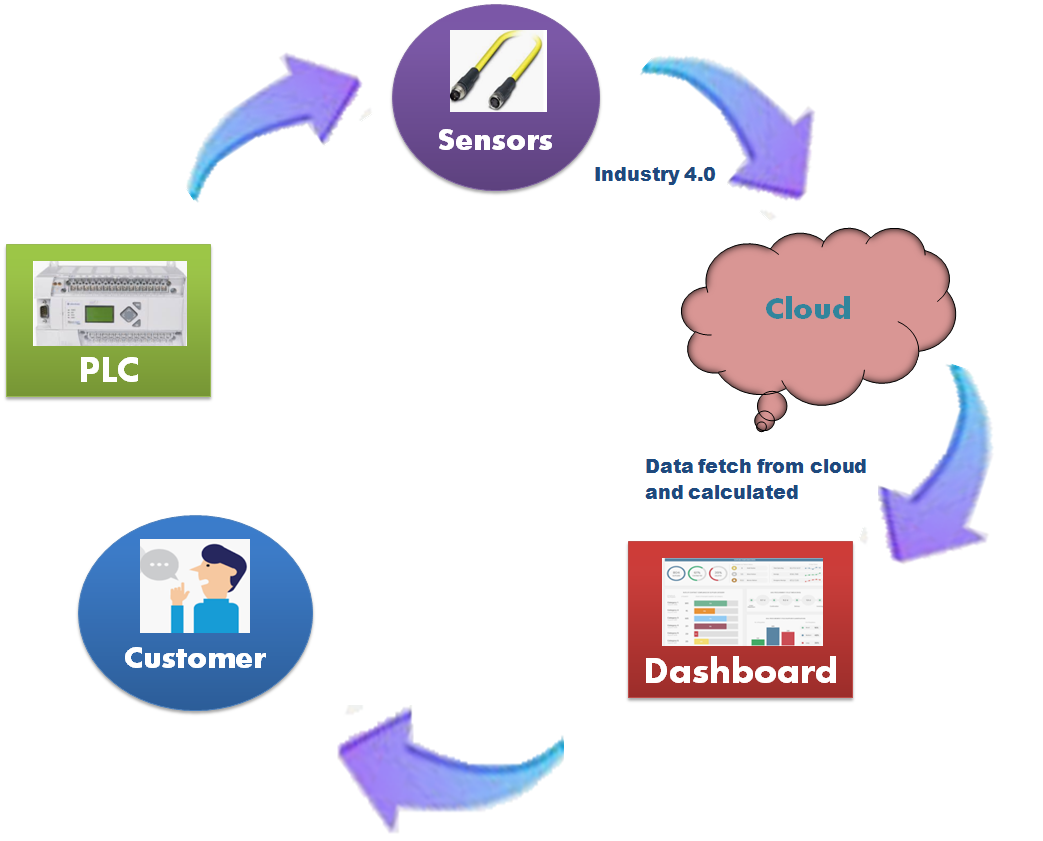

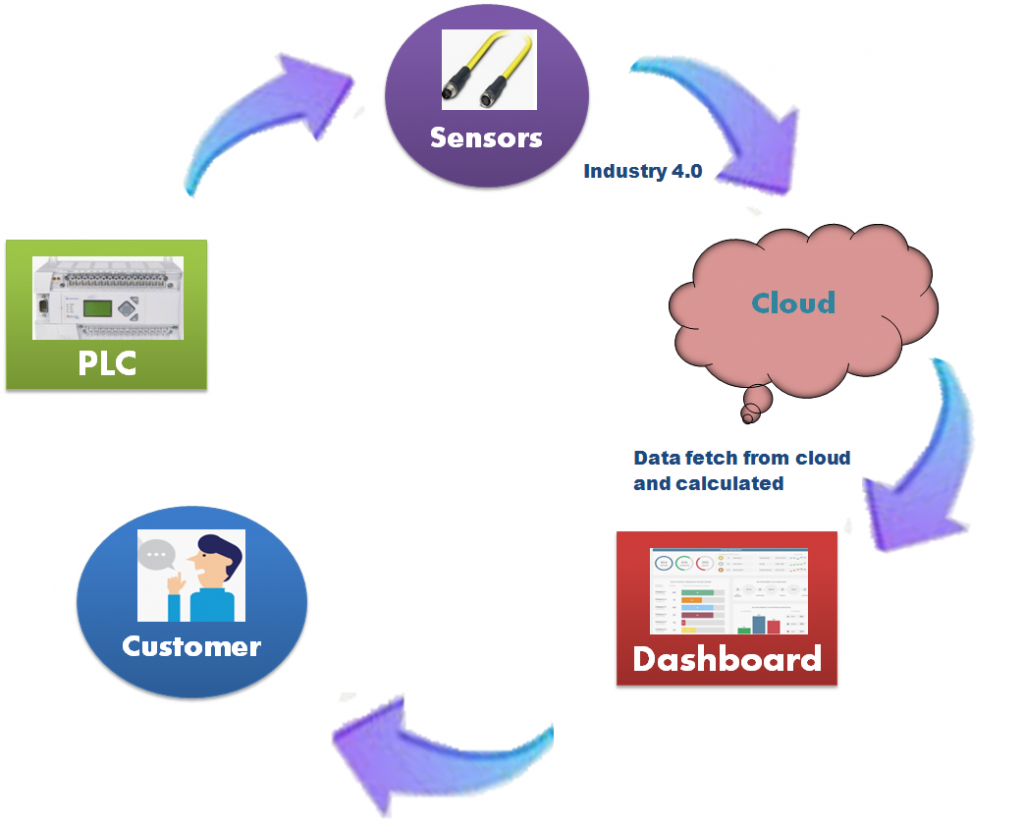

Cloud Computing Platform:

Industrial cloud applications are used for capturing and accessing the data which is fast, helpful for easy updates and can be accessed on mobile or desktops as per the convenience.

-

Advanced Analytics:

IIOT has the ability to receive constant information from sensors and respond with analysed data in real time. It makes machine learning very powerful tool in providing benefits in production through IIOT.

IIOT has helped with predictive maintenance, the behaviour can be very well understood of machines with their real time data. The machines can be well identified with accuracy for the errors and malfunctioning.

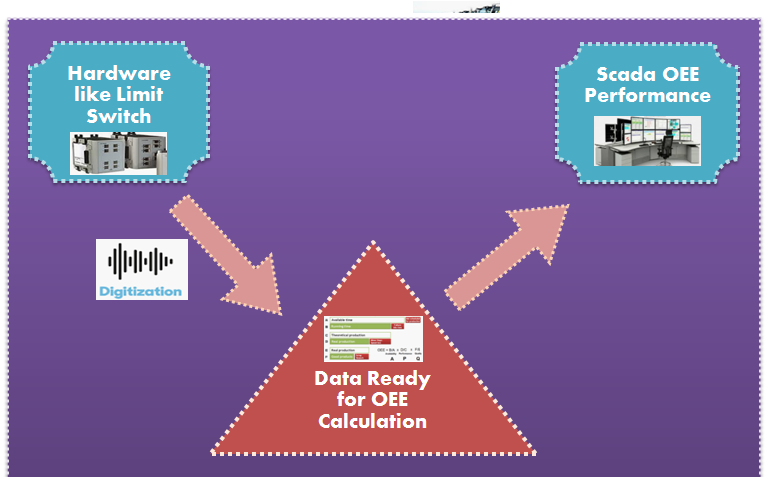

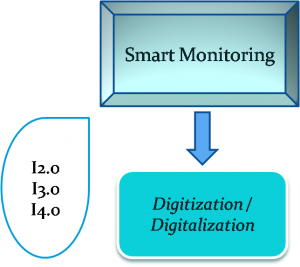

Digital transformation is vital aspect for IIOT implementation in a manufacturing process. The digitization should cover all the aspects of Industry which includes production, development, delivery, quality and analysis.