IIoT Solutions:

In today’s rapidly evolving industrial landscape, businesses are constantly seeking ways to improve efficiency, reduce costs, and gain a competitive edge. The Industrial Internet of Things (IIoT) has emerged as a transformative technology, offering unprecedented opportunities for innovation and growth. By connecting industrial equipment, systems, and processes through a network of sensors and software, IIoT solutions empower businesses to unlock valuable insights, optimize operations, and drive significant improvements across the entire value chain.

Key Benefits of IIoT Solutions:

- Enhanced Efficiency and Productivity:

- Real-time data monitoring and analysis enable proactive maintenance, minimizing downtime and maximizing equipment utilization.

- Automated processes streamline workflows, reducing manual labor and human error.

- Predictive analytics can identify potential bottlenecks and optimize production schedules.

- Improved Quality and Consistency:

- Consistent data collection and analysis ensure product quality and consistency across all stages of production.

- Real-time feedback loops enable rapid adjustments to manufacturing processes.

- Advanced analytics can identify root causes of defects and implement corrective actions.

- Reduced Costs and Increased Profitability:

- Predictive maintenance minimizes unexpected equipment failures, reducing costly repairs and replacements.

- Optimized resource utilization minimizes waste and energy consumption.

- Improved efficiency and productivity directly translate to increased profitability.

- Enhanced Safety and Security:

- Real-time monitoring of safety conditions allows for early detection and response to potential hazards.

- Remote access and control capabilities improve operational flexibility and reduce the need for on-site personnel.

- Robust cybersecurity measures protect critical infrastructure and sensitive data.

- Data-Driven Decision Making:

- Access to real-time data and advanced analytics provides valuable insights for informed decision-making.

- Businesses can identify trends, anticipate future needs, and make data-driven adjustments to their operations.

- Improved decision-making leads to better business outcomes and increased competitiveness.

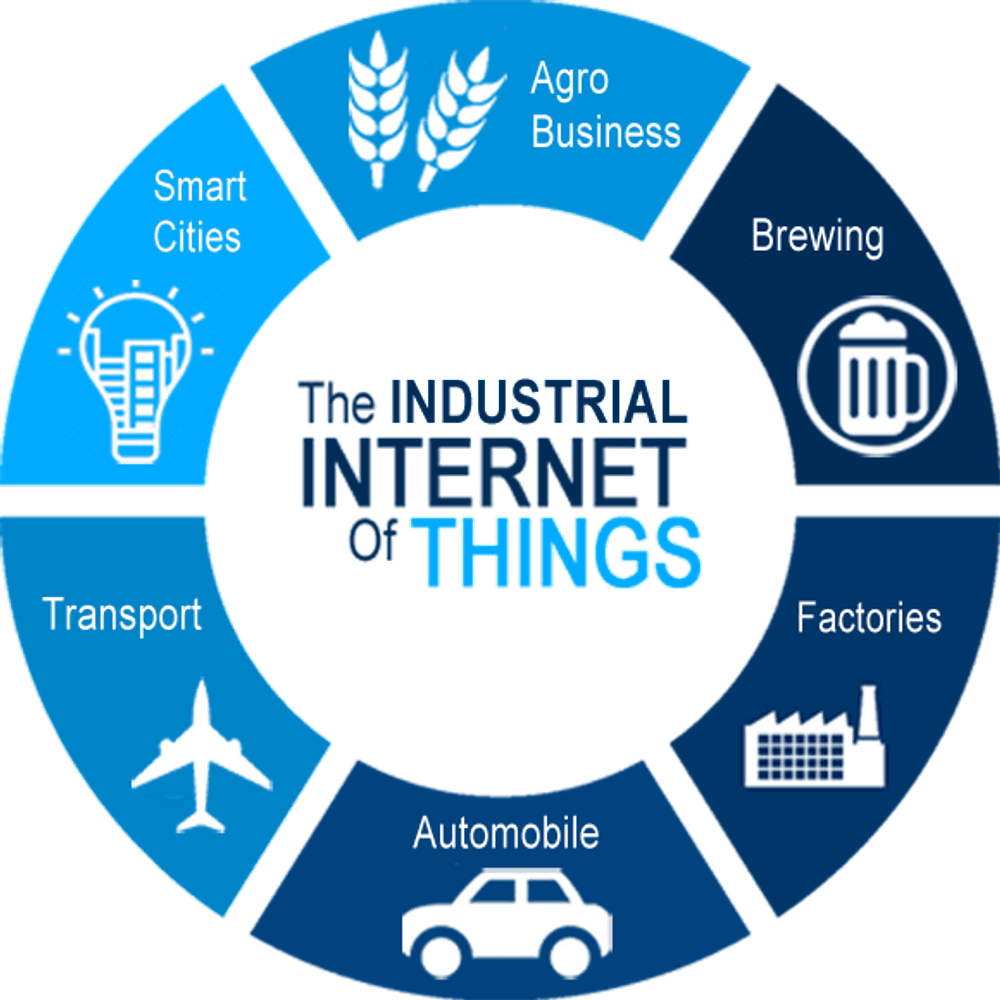

IIoT Applications Across Industries:

- Manufacturing: Predictive maintenance, quality control, supply chain optimization, production automation.

- Energy: Smart grids, renewable energy integration, demand-side management, energy efficiency optimization.

- Healthcare: Remote patient monitoring, precision medicine, connected medical devices, hospital operations management.

- Transportation: Connected vehicles, autonomous driving, logistics optimization, predictive maintenance of vehicles and infrastructure.

- Agriculture: Precision farming, livestock monitoring, resource management, yield optimization.

IIoT solutions are revolutionizing industries worldwide, offering unprecedented opportunities for efficiency, innovation, and growth. By embracing the power of connected technologies, businesses can unlock their full potential, gain a competitive advantage, and thrive in the digital age.