Transformation of Manufacturing Industry through Digitization

Definition of Digitization:

Industry Digitization is the first step towards Industrial Internet of Things (IIOT). In simple words digitization is a process of turning non-digital formats of information into digital formats. Like clay models into CAD files, letters into emails, hardcopy report files in excel reports etc.

Most important point is to keep the processes and systems same when processes are digitized. It is also called making the industry go Paperless.

Few transformations in manufacturing industries:

Here are few transformations that will take place in manufacturing industries if digitization is introduced:

- Speed of Manufacturing will Increase

The speed of manufacturing industry is going to increase with digital transformation,

For instance the system will move fast from design to floor and back again as the changes required from engineering team.

Now days the process is manual in many cases. First 3D designs are converted into 2 D books and then 2D books are delivered to machinist to review and then the same is returned to engineering team for amendment if any.

The inefficiency that is taking place in manufacturing industries is:

- It consumes lot of time and man hours.

- Factories are usually globalized sending exact information may get time taking.

- No auto-check facility and it is tedious task to further innovate to optimize the process.

Hence, Digitization makes the process more efficient and fast.

- Making the manufacturing process globalized:

We all know, in any manufacturing industry there are different plants operating same or different processes related to the specific product. Through digitization we can share the data globally without any delay.

For instance as one plant closes for the day and the other one with different time zone is opening up , required data or information can be shared seamlessly without any downtime.

Thus, digitization enables to share the essential data in real time across multiple global locations.

Also, enabling data to be accessed in real time across different places in the world impact on innovation trends and creates new opportunities.

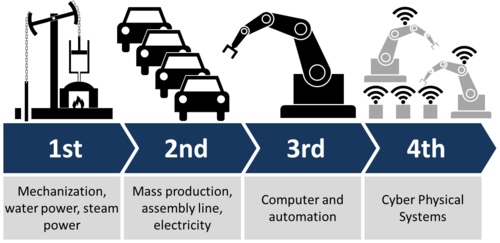

Once the processes are digitized then additional technologies like machine learning, AR, IIOT, machine intelligence, IIOT, Industry 4.0 and complete life cycle can emerge.