The Power of Prediction: How Predictive Maintenance Turbocharges Industrial Efficiency and Savings

In the competitive landscape of industrial business, operational efficiency isn’t just a buzzword—it’s the lifeblood of profitability. For too long, maintenance strategies have been reactive (waiting for a breakdown) or purely preventive (scheduled, often unnecessary, upkeep). Enter Predictive Maintenance (PdM): a data-driven, game-changing approach that is revolutionizing asset management, delivering massive cost savings, and fundamentally improving operational efficiency across sectors like manufacturing, energy, and transportation.

The Flaws in Traditional Maintenance Models

To truly appreciate the value of PdM, we must first understand the limitations of older models:

- Reactive Maintenance (Run-to-Failure): This approach is simple: fix it when it breaks. While zero upfront cost, the result is often catastrophic and expensive. An unexpected failure means unplanned downtime, emergency repairs costing 3-5 times more than planned work, rushed parts delivery, and potential safety risks. In the manufacturing sector alone, unplanned downtime costs industries an estimated $50 billion annually.

- Preventive Maintenance (Time-Based): This involves scheduled maintenance, regardless of the asset’s actual condition. While it reduces the risk of some failures, it often leads to over-maintenance. You end up wasting money and labor on servicing equipment that is perfectly healthy, prematurely replacing components with significant remaining lifespan, and incurring unnecessary planned downtime.

Predictive Maintenance bridges this gap. It’s not about guessing or waiting; it’s about knowing the optimal time to intervene, turning a historically costly overhead into a strategic competitive advantage.

Significant Cost Savings Through Smarter Intervention

The shift to a data-driven PdM strategy creates financial benefits that ripple across the entire organization. Industry studies consistently show that PdM can yield cost savings of 8% to 12% over preventive maintenance and up to 40% over purely reactive maintenance.

1. Eliminating the High Cost of Unplanned Downtime

This is arguably the most significant financial win. Unplanned downtime halts production, leading to lost revenue, missed deadlines, and contractual penalties.

- The PdM Solution: By continuously monitoring key operational parameters like vibration, temperature, pressure, and acoustic emissions using IoT sensors and advanced analytics, PdM algorithms can detect subtle anomalies that indicate an impending failure. This allows maintenance teams to schedule repairs weeks in advance, precisely when needed, and during planned shutdowns or low-demand periods.

- The Financial Impact: By moving maintenance from a chaotic emergency to a scheduled event, businesses minimize production interruption and significantly reduce the average cost of a breakdown, which can run into hundreds of thousands of dollars per hour for critical assets.

2. Optimizing Maintenance Resource Allocation

PdM ensures that maintenance efforts are precisely targeted, leading to efficient use of time and budget.

- The PdM Solution: Instead of performing blanket inspections or unnecessary component replacements based on a calendar, PdM directs technicians exactly where the problem is and when it needs attention. Furthermore, the early warning allows for standard, lower-cost work orders instead of expensive emergency service calls.

- The Financial Impact: This results in 25-30% reduction in overall maintenance costs, lower labor costs, and a dramatic decrease in wasted spare parts inventory, as procurement can be planned precisely for the required intervention time.

3. Extending Asset Lifespan and Improving ROI

A machine that is consistently operating in its optimal performance window lasts longer.

- The PdM Solution: By catching minor issues (like slight misalignment or bearing wear) before they escalate into major catastrophic failures, PdM prevents cumulative damage to critical and expensive components.

- The Financial Impact: This extends the operational life of equipment by 20-30%, delaying the need for costly capital expenditure on replacement machinery. It maximizes the return on the initial investment in industrial assets.

Enhanced Operational Efficiency and Performance

Cost savings are only half the story; PdM also fundamentally improves how the business operates.

1. Maximizing Overall Equipment Effectiveness (OEE)

OEE is the gold standard for measuring manufacturing productivity, factoring in availability, performance, and quality. PdM directly impacts all three.

- Availability: Minimizing downtime (both unplanned and unnecessary planned maintenance) directly increases the time the machine is running.

- Performance: A machine operating in optimal condition, as ensured by timely and condition-based maintenance, runs faster and more reliably.

- Quality: Preventing failures means fewer production runs are affected by equipment-induced defects, leading to higher first-pass yield.

2. Better Strategic Planning and Inventory Management

Predictable maintenance leads to predictable operations, which allows for better business-wide planning.

- Inventory: Knowing exactly when a part will be needed allows companies to move from carrying large, expensive buffer stocks to a just-in-time inventory model for spare parts, reducing warehousing costs and mitigating the risk of obsolescence.

- Workforce: Maintenance managers can level-load their teams’ schedules, avoid over-reliance on overtime, and strategically allocate specialized technical skills where they are most critically needed.

3. Improved Safety and Environmental Compliance

Healthy machines are safer machines. The early detection of faults like overheating, excessive vibration, or leaks reduces the risk of catastrophic failures that could injure personnel or cause environmental hazards. Additionally, optimally running equipment often consumes less energy, contributing to sustainability goals.

The Technology Behind the Transformation

Implementing a successful PdM strategy relies on the convergence of three key technologies:

- Industrial IoT (IIoT) Sensors: Affordable, rugged sensors (for vibration, thermal imaging, acoustics, etc.) placed on critical equipment collect real-time data on the asset’s health.

- Big Data and Cloud Computing: This infrastructure is needed to collect and store the vast torrent of data generated by thousands of sensors.

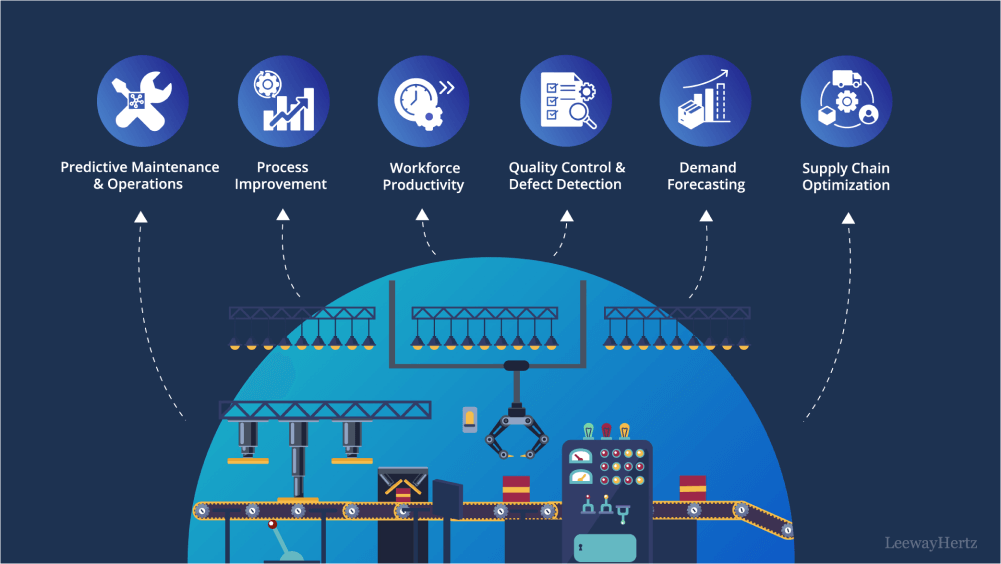

- Artificial Intelligence (AI) and Machine Learning (ML): These advanced analytical tools are the true brains of PdM. They process the sensor data, identify patterns and anomalies that human operators might miss, and—crucially—generate the predictive models that forecast the remaining useful life (RUL) of an asset or component.

Conclusion: The Future of Industrial Operations is Predictive

Predictive Maintenance is not merely an upgrade from old maintenance practices; it is a strategic transformation that leverages the power of data to create a lean, highly reliable, and immensely profitable industrial operation. By turning unexpected crises into scheduled events, industrial businesses are not just saving money; they are unlocking new levels of productivity, asset utilization, and competitive resilience. The return on investment for a well-executed PdM program is rapid and substantial, making it an essential component of the modern, smart industrial enterprise.