Automation Meets Safety: Mask Detection with Machine Interlocking in Enzymatic Environments

In an enzymatic powder environment—such as detergent manufacturing, food processing, or pharmaceutical labs—mask compliance isn’t just about “safety protocol.” It’s a critical barrier against respiratory sensitization and occupational asthma caused by inhaling bioactive dust.

Here is a comprehensive blog post structure and content designed for a technical yet industry-focused audience.

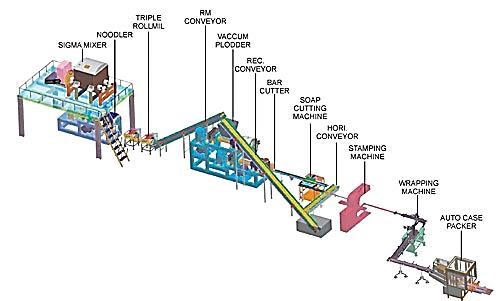

In the world of industrial manufacturing, particularly where enzymatic powders are handled, the air we breathe is a potential hazard. While enzymes are biological catalysts that make our soaps cleaner and our bread fluffier, inhaling them in powder form can lead to severe allergic reactions and long-term respiratory issues.

The solution? An intelligent, AI-driven Mask Detection System that doesn’t just “alert” but actually controls the machinery.

The Challenge: Why Enzymes Require Zero-Tolerance

Enzymatic dust is highly sensitizing. Standard safety signage often fails because of “compliance fatigue”—workers rushing to clear a jam or check a hopper may forget their PPE for “just a second.” In a high-risk enzymatic zone, that second is enough for exposure.

The Solution: AI Computer Vision + PLC Integration

A “Mask Detection with Machine Control” system uses high-speed cameras and Edge AI to ensure that no human can interact with the production line unless they are properly protected.

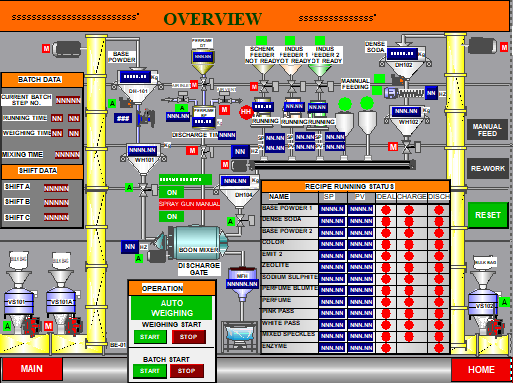

How the System Works

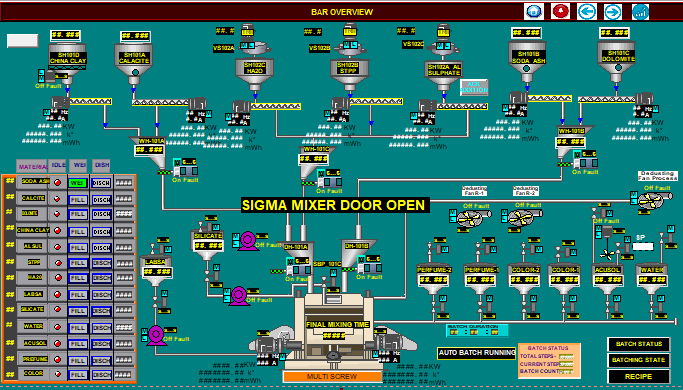

- Vision Acquisition: Industrial-grade cameras monitor “Safe Zones” or entry points near powder-dispensing units.

- Neural Network Analysis: The AI (usually a YOLO—You Only Look Once—v8 or v10 model) identifies the presence of a person and specifically looks for the seal of an N95 or P3 respirator.

- Machine Interlocking: The AI system is interfaced with a Programmable Logic Controller (PLC) via a dry contact relay or industrial protocol (like Modbus or MQTT).

- The “Kill Switch” Logic: * Mask Detected: Machine continues normal operation.

- No Mask/Improper Fit: The PLC triggers an immediate E-stop or prevents the machine from starting, locking the enzymatic dispenser until the worker complies.

Technical Architecture

To ensure the system is robust enough for a dusty industrial environment, the hardware and software must be specialized:

| Component | Specification |

| Camera | IP67-rated (Dustproof) with built-in lens cleaning or air-purge |

| Edge Gateway | NVIDIA Jetson Orin or similar for real-time, low-latency processing |

| AI Model | Custom-trained CNN (Convolutional Neural Network) focused on PPE textures |

| Interface | Industrial Relay or Digital I/O to the Machine’s Safety Circuit |

Key Benefits for Enzymatic Facilities

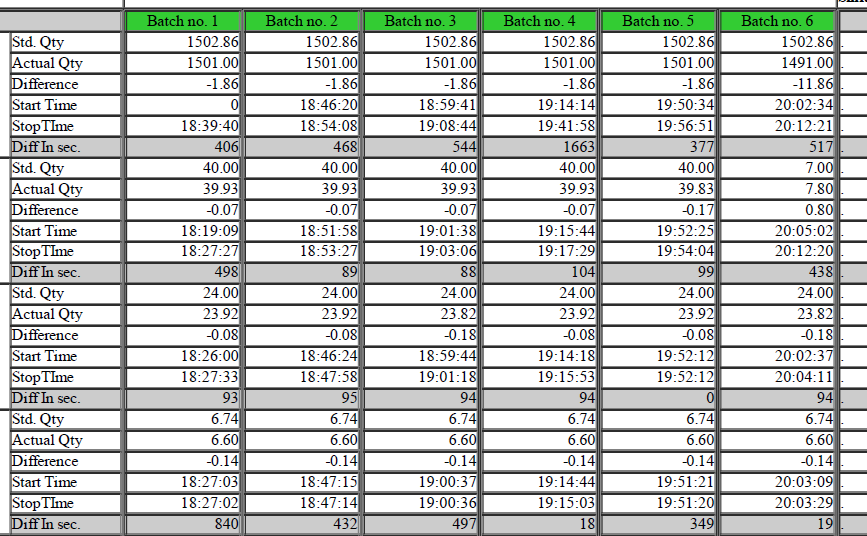

- Reduced Liability: Automated logging of PPE compliance provides a digital audit trail for health and safety regulators (OSHA/HSE).

- Instant Feedback: Visual and audible alarms notify the worker immediately, correcting the behavior before exposure occurs.

- Operational Integrity: Prevents cross-contamination. If a worker isn’t masked, they shouldn’t be near the open enzymatic batches, protecting both the worker and the product purity.

Beyond Detection: Addressing the “False Sense of Security”

It is important to note that detection is only half the battle. In enzymatic environments, the fit of the mask is as important as the mask itself. Advanced systems are now being trained to detect “chin-masking” (wearing the mask below the nose), ensuring the interlock only releases when the respiratory tract is fully covered.

Safety Note: Machine control systems should always include a manual override for emergency maintenance, protected by “Lock-Out, Tag-Out” (LOTO) procedures.

Conclusion

Integrating AI mask detection with machine control transforms PPE from a “suggestion” into a fundamental requirement for machine operation. In the high-stakes environment of enzymatic powder handling, this technology is the ultimate fail-safe for employee longevity and plant safety.