Maximizing Productivity and Profit: The Primary Goal of OEE

In today’s competitive manufacturing landscape, the drive for efficiency and profitability is relentless. Companies are constantly seeking ways to squeeze more value from their existing assets, minimize waste, and produce higher-quality goods, faster. While various methodologies and tools exist to address these needs, few are as fundamental and impactful as the implementation of an Overall Equipment Effectiveness (OEE) solution.

The primary goal of implementing an OEE solution is straightforward yet profoundly transformative: to provide a comprehensive, quantitative understanding of how effectively a manufacturing operation is utilized, thereby enabling targeted improvement initiatives to maximize productivity and profitability.

Simply put, OEE gives you the crucial, unbiased data you need to stop guessing and start fixing.

Deciphering the OEE Score

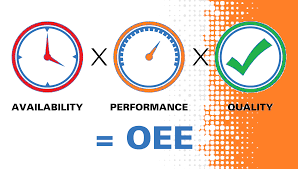

OEE isn’t just a single number; it’s a powerful metric derived from three key factors that quantify the true productivity of a piece of equipment or an entire production line. Understanding these components is essential to achieving the primary goal.

1. Availability

Availability measures the amount of time the equipment was actually running productively compared to the time it was scheduled to run.

- The Goal: Minimize Downtime Losses. An OEE solution identifies and quantifies all reasons for planned and unplanned stops, such as equipment breakdowns, material shortages, setups, and changeovers. By highlighting these losses, it focuses efforts on improving maintenance strategies, reducing changeover times, and ensuring timely material delivery.

2. Performance

Performance measures how fast the equipment ran when it was running, compared to its maximum potential speed (ideal cycle time).

- The Goal: Minimize Speed Losses. This metric catches losses from equipment running slower than its designed speed. These losses are often subtle and include minor stops (jams, sensor issues) and reduced speed operation. By identifying these hidden capacity issues, the OEE solution helps restore equipment to its peak operating speed.

3. Quality

Quality measures the number of good parts produced compared to the total number of parts started.

- The Goal: Minimize Quality Losses. This factor accounts for all scrap, rework, and parts that do not meet quality specifications. By tracking defects, an OEE solution can help pinpoint the exact time and conditions under which quality issues occur, enabling root cause analysis to prevent future defects.

The Power of Focus: Moving Beyond the Metric

While the OEE score itself is the ultimate benchmark, the true value of the solution lies in the ability to drill down into the six big losses—the specific reasons why production is suffering.

The primary goal is achieved by leveraging the OEE solution to:

🎯 Create a Baseline and Benchmark Performance

Before OEE, manufacturers often relied on guesswork or siloed data. An OEE solution provides a single, objective, and consistent metric to establish a true baseline of current performance. This allows management to set realistic, data-driven targets and benchmark different lines, shifts, or facilities against one another.

💰 Drive Capital-Free Capacity Gains

Often, the fastest way to increase output isn’t to buy new equipment, but to make the existing equipment work better. OEE implementation almost always reveals significant hidden capacity—time that was being lost to avoidable stops, slow speeds, or poor quality. Recovering this time translates directly into increased production volume without major capital expenditure. This is a massive driver of profitability.

🛠️ Shift to Proactive Maintenance

By accurately tracking downtime reasons, OEE data provides the foundation for moving away from costly, unpredictable reactive maintenance (fixing things only when they break) to a more efficient predictive or preventive maintenance schedule. Focusing maintenance resources on the assets and failure modes that most significantly impact OEE reduces unplanned downtime.

🤝 Foster Cross-Functional Collaboration

OEE is a universal language on the plant floor. It bridges the gap between operations, maintenance, and quality departments. When a line’s OEE drops, it’s clear whether the loss is due to a mechanical breakdown (Maintenance), an operator error (Operations), or a process issue (Quality). This data drives collaboration and ensures all teams are aligned on the single goal of continuous improvement.

The Return on Investment (ROI)

The primary goal of implementing an OEE solution culminates in a measurable, positive return on investment (ROI). This is realized through:

- Increased Throughput: Producing more goods with the same assets.

- Lower Operating Costs: Reducing waste (scrap), energy usage, and maintenance expenses.

- Improved Quality: Lowering defect rates and enhancing customer satisfaction.

- Faster Time to Market: Increased efficiency allows for quicker fulfillment of orders.

In conclusion, implementing an OEE solution is not just about tracking a metric; it is an investment in a data-driven culture of continuous improvement. By quantifying performance losses into the clear categories of Availability, Performance, and Quality, the OEE solution provides the actionable insights necessary to unlock the full potential of manufacturing assets, making the primary goal of maximizing productivity and profitability an achievable reality.