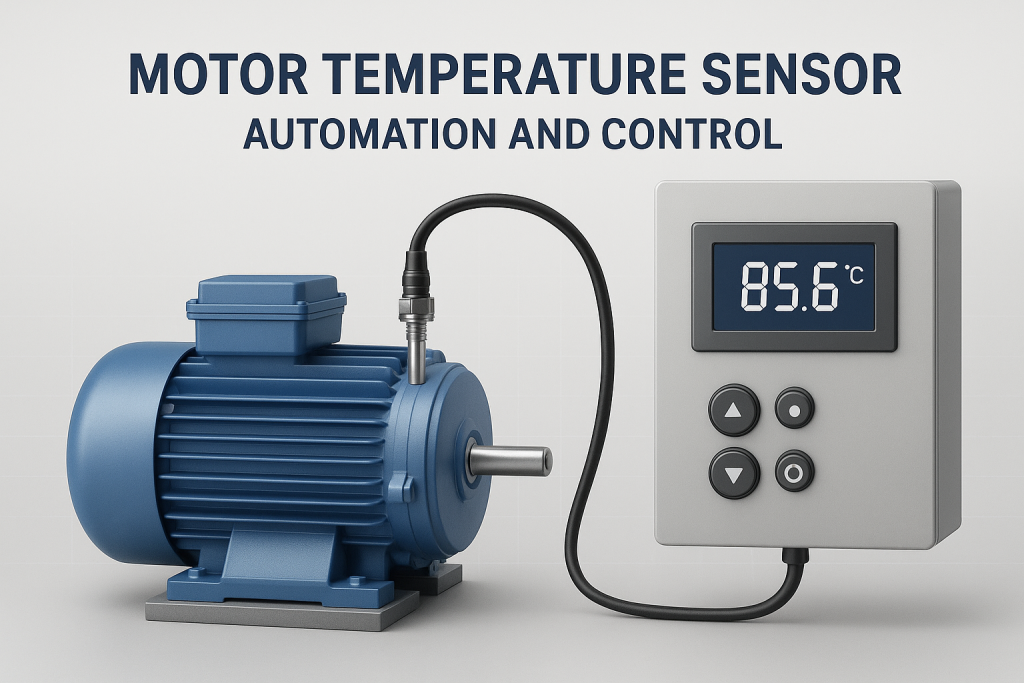

A motor temperature sensor is a critical component in automation that measures the temperature of an electric motor. These sensors are essential for monitoring a motor’s health and preventing damage caused by overheating. Overheating can lead to reduced efficiency, insulation breakdown, and catastrophic motor failure.

Why Motor Temperature Sensors are Crucial in Automation

In industrial automation, electric motors are the workhorses of countless machines, from conveyor belts to robotic arms. Their continuous operation generates heat, and if not properly managed, this heat can severely damage the motor’s internal components. Motor temperature sensors provide real-time data, allowing a control system (like a Programmable Logic Controller or PLC) to take proactive measures, such as:

- Triggering Alarms: Alerting operators to potential overheating issues before they become critical.

- Reducing Load or Speed: Automatically adjusting the motor’s workload to lower its temperature.

- Shutting Down the System: Initiating a safe shutdown to prevent permanent damage to the motor and other equipment.

This real-time monitoring capability is a cornerstone of predictive maintenance, shifting the approach from reactive repairs (fixing a motor after it has failed) to proactive prevention.

Types of Motor Temperature Sensors

There are several types of temperature sensors commonly used in motors, each with its own advantages and applications.

1. Thermistors

Thermistors are resistors whose resistance changes significantly with temperature. There are two main types:

- Negative Temperature Coefficient (NTC) Thermistors: Their resistance decreases as temperature increases. They are highly sensitive and provide a fast response.

- Positive Temperature Coefficient (PTC) Thermistors: Their resistance increases as temperature increases. They are often used as a thermal switch; their resistance changes drastically at a specific “switching” temperature, making them ideal for triggering a shutdown.

2. Resistance Temperature Detectors (RTDs)

RTDs, such as the widely used PT100 and PT1000 sensors, are known for their high accuracy and stability. They operate on the principle that the resistance of a metal (typically platinum) changes linearly with temperature. While slower to respond than thermistors, their precision makes them suitable for applications where accurate temperature readings are paramount.

3. Thermocouples

A thermocouple consists of two different metal wires joined at one end. When the junction is heated, it generates a small voltage that is proportional to the temperature. Thermocouples are durable, can withstand extremely high temperatures, and have a wide measurement range, making them suitable for high-temperature environments or motors operating under extreme conditions.

Integration and Solutions in Automation

Integrating a motor temperature sensor into an automation system involves more than just placing the sensor on the motor. A complete solution includes:

- Sensor Placement: Sensors are typically embedded in the motor windings, where they can provide the most accurate reading of the core temperature. For larger motors, multiple sensors may be used to monitor different points.

- Signal Conditioning: The weak electrical signal from the sensor needs to be converted into a usable format. This is done by a transmitter or signal conditioner which amplifies and linearizes the signal.

- Control System Interface: The conditioned signal is fed into a PLC or a dedicated motor protection relay. The control system uses this data to make decisions based on programmed logic.

- Human-Machine Interface (HMI): The motor’s temperature and status are often displayed on an HMI, providing operators with a visual overview of the system’s health.

A robust motor temperature monitoring solution provides a clear return on investment by reducing downtime, extending the lifespan of expensive equipment, and ensuring the safety of personnel and operations. It’s a fundamental component of any modern, reliable, and efficient automation system.