The ROI of Resonance: Is Vibration Condition Monitoring a Cost-Effective Strategy for Predictive Maintenance?

In the industrial world, the phrase “cost-effective” is the ultimate barometer of a maintenance strategy’s success. As businesses transition from traditional, reactive maintenance (fixing things after they break) to predictive maintenance (PdM), a key question arises: Does the investment in Vibration Condition Monitoring (VCM) truly pay off?

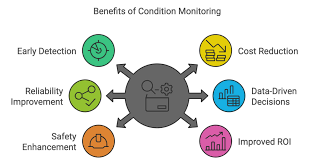

The answer, supported by decades of industrial data and case studies, is a resounding yes. VCM is not merely a technical upgrade; it is a strategic financial investment that provides an exceptional Return on Investment (ROI) by mitigating catastrophic risk, optimizing resource use, and fundamentally changing the cost structure of maintenance.

The True Cost of Reactive Maintenance

To understand VCM’s value, one must first recognize the exorbitant hidden costs of waiting for equipment to fail—the reactive approach.

- Catastrophic Downtime: The single largest cost. Unscheduled machine failure can halt an entire production line, leading to lost revenue, missed deadlines, and contractual penalties. For a major plant, this cost can easily exceed $10,000 to $50,000 per hour.

- Secondary Damage: When a component fails (e.g., a bearing seizure), it often damages surrounding, expensive parts like shafts, casings, or impellers, turning a simple repair into a complete rebuild.

- Emergency Labor and Parts: Reactive work requires overtime pay for technicians and premium shipping costs for rush-ordered spare parts, inflating labor and material expenses significantly.

- Reduced Equipment Lifespan: Operating equipment that is known to be vibrating excessively (even if not yet failed) accelerates wear on all components, shortening the machine’s overall useful life.

How VCM Drives Cost-Effectiveness: The ROI Breakdown

Vibration Condition Monitoring transforms these reactive costs into manageable, planned expenses, creating a compelling financial argument for its implementation.

1. Significant Reduction in Maintenance Costs (The Core Savings)

By allowing maintenance to be scheduled and planned precisely when needed, VCM cuts co2. Optimizing Spare Parts Inventory

VCM provides accurate forecasts of when a specific component (e.g., a pump bearing) will reach its critical limit.

- Just-In-Time Inventory: Instead of keeping large, expensive stocks of critical spares “just in case” (tying up capital), companies can order parts only a few weeks or days before they are needed.

- Avoiding Obsolescence: Reduces the risk of holding stock that becomes obsolete before it is ever used.

3. Energy Efficiency and Performance Enhancement

A machine that is running poorly due to faults like misalignment or imbalance consumes significantly more energy than a machine operating within optimal mechanical tolerances.

- Misalignment: When shafts are misaligned, they create friction and vibration, forcing the motor to draw more current to perform the same amount of work.

- VCM as a Performance Tool: Correcting a severe imbalance identified by VCM not only prevents failure but immediately lowers the power draw, leading to tangible, ongoing utility cost savings.

4. Maximizing Asset Lifespan and Capital Preservation

VCM enforces good operating practices. By ensuring that machines are consistently balanced, aligned, and free of defects, they run cooler, experience less stress, and ultimately last longer.

- Deferred Capital Expenditure: Extending the life of a major asset—such as a large compressor or turbine—by just a few years can defer millions in capital expenditure for replacement. The VCM program effectively protects the original capital investment.

Conclusion: VCM as a Must-Have Investment

Vibration Condition Monitoring is undoubtedly a cost-effective strategy for predictive maintenance. It shifts expenditure from unpredictable, high-stakes emergency repairs to calculated, managed, and planned preventive interventions.

The initial investment in VCM technology (sensors, data collectors, and software) is quickly offset by the tangible reduction in downtime, lower labor costs, minimized secondary damage, and improved asset longevity. For any industrial operation where rotating equipment is critical to production, VCM is not a luxury—it is an essential financial and operational safeguard that delivers superior long-term returns.