How do you secure a SCADA network against modern 2026 cyber threats?

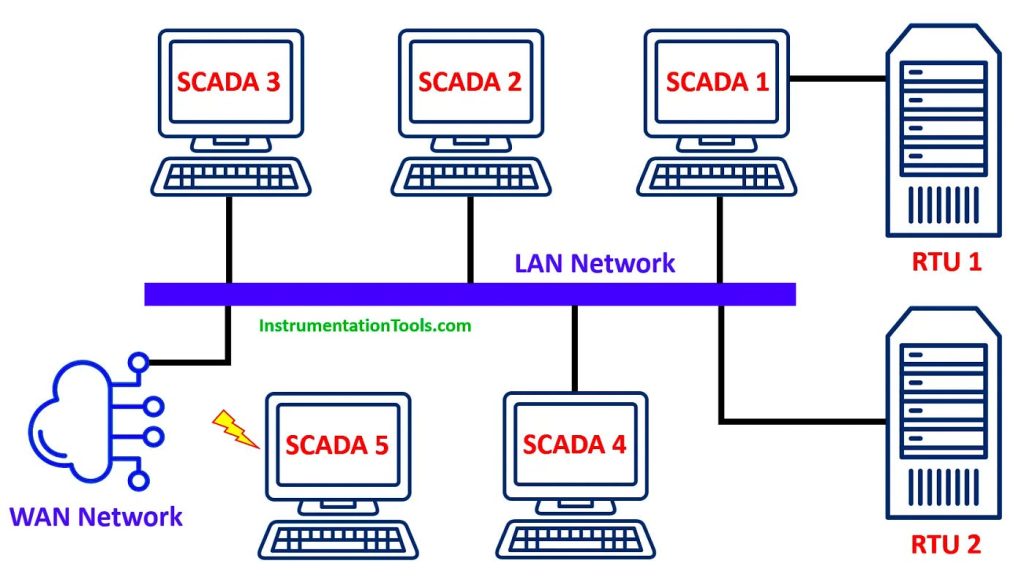

In 2026, the “air-gap” is officially a myth. As industrial facilities integrate AI-driven analytics and remote edge computing, the attack surface for SCADA systems has expanded from local control rooms to the global cloud.

Securing a SCADA network today requires moving beyond simple firewalls. To defend against the sophisticated, autonomous, and identity-centric threats of 2026, facilities must adopt a “Resilience-First” posture.

1. Implement a Zero-Trust Architecture (ZTA)

The “trust but verify” model is dead. In a modern SCADA environment, the guiding principle is “Never Trust, Always Verify.”

-

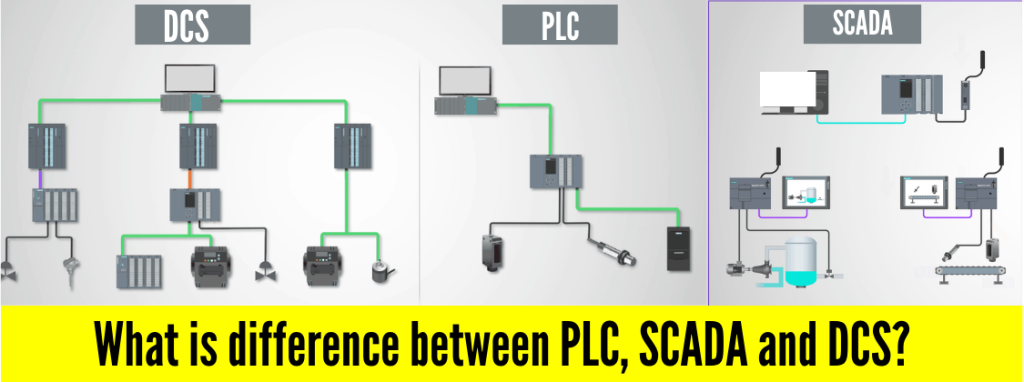

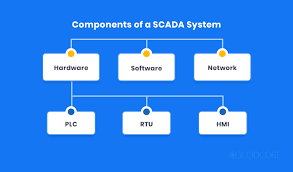

Identity as the New Perimeter: With the rise of AI-powered credential theft, IP addresses are no longer reliable identifiers. Access to PLCs or HMIs must be granted based on multi-factor authentication (MFA) and hardware-based keys (like FIDO2 passkeys).

-

Micro-Segmentation: Traditionally, networks were segmented by “zones” (e.g., the Purdue Model). In 2026, we use micro-segmentation to isolate individual processes. If an attacker compromises a single workstation, the lateral movement to the water pumps or power breakers is physically blocked by software-defined perimeters.

2. Deploy AI-Driven Behavioral Analytics

Static, signature-based antivirus cannot keep up with the polymorphic malware and agentic AI attacks of 2026.

-

Anomaly Detection: Instead of looking for “known bad” files, modern security tools use machine learning to establish a “baseline of normal.” If a PLC that usually sends 10KB of data suddenly starts sending 5MB to an unknown external IP, the system automatically kills the connection.

-

Predictive Threat Hunting: Advanced AI agents now “proactively” scan your own network for vulnerabilities, simulating attacks to find weak points before a human (or a malicious AI) does.

3. Protect the “Software Bill of Materials” (SBOM)

Supply chain attacks—where hackers compromise a vendor’s update server—are a primary threat in 2026.

-

SBOM Transparency: You must demand an SBOM for every piece of software in your SCADA stack. This is a list of every library and component used in the code. When a new vulnerability (like a future version of Log4j) is announced, you can instantly see if your systems are affected.

-

Signed Updates: Ensure your MTU and field devices only accept firmware updates that are digitally signed and verified through a secure hardware security module (HSM).

4. Transition to Quantum-Resistant Encryption

As quantum computing inches closer to practical reality, “harvest now, decrypt later” attacks have become a genuine concern for critical infrastructure with long lifecycles.

-

Post-Quantum Cryptography (PQC): Modern SCADA systems are now integrating NIST-approved quantum-resistant algorithms for data at rest and in transit.

-

End-to-End Encryption: Even on internal serial-over-ethernet links, data must be encrypted. In 2026, unencrypted “plain text” protocols (like basic Modbus) are considered a critical safety violation.

5. Formalize “Operational Resilience” (Not Just Security)

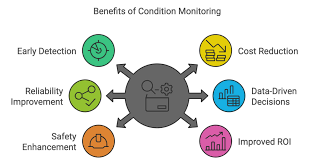

In the 2026 threat landscape, the question isn’t if you will be breached, but how fast you can recover.

-

Immutable Backups: Store your SCADA configurations and historian data in “write-once-read-many” (WORM) drives. This prevents ransomware from encrypting your backups.

-

The OT Digital Twin: Use a digital twin to test security patches before deploying them to the live floor. This ensures that a security update doesn’t accidentally cause a physical valve to malfunction or a motor to overheat.

-

Incident Response Orchestration: Use automated playbooks to handle common threats. If a “Living off the Land” attack is detected, the system can automatically isolate the affected segment while keeping the rest of the plant running in “manual override” mode.

The New Standard: NIST SP 800-82 Rev. 3

The latest industry guidelines shift the focus from “Industrial Control Systems” (ICS) to the broader “Operational Technology” (OT) environment. Compliance with these standards is no longer optional for regulated industries—it is the baseline for insurance and legal operation.

Would you like me to help you draft a “Cybersecurity Checklist” specifically for field technicians to use during their weekly inspections?