SCADA vs. DCS: Which control system does your facility actually need?

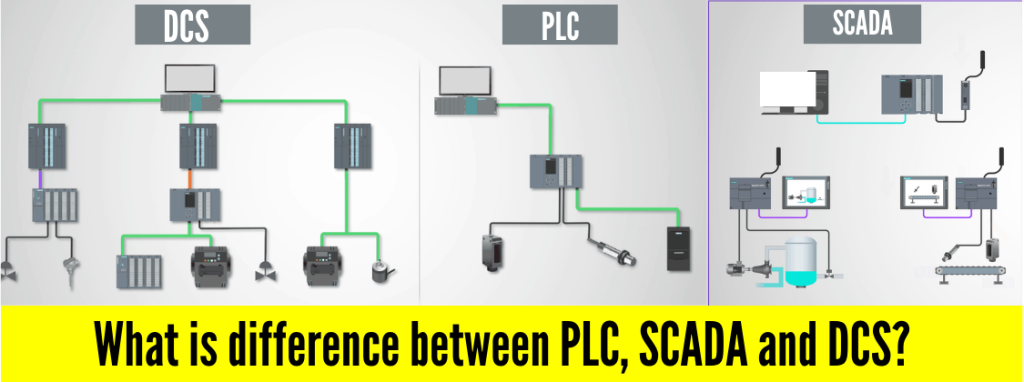

Choosing the right control system is one of the most consequential decisions a plant manager or systems engineer can make. For decades, the debate has centered on SCADA (Supervisory Control and Data Acquisition) vs. DCS (Distributed Control System).

While the lines between them are blurring in the era of Industry 4.0, choosing the “wrong” one can lead to massive cost overruns or, worse, a system that lacks the precision or reach your facility requires.

Here is a deep dive into which system your facility actually needs.

1. The Core Philosophy: Process vs. Data

The fundamental difference lies in what the system was designed to prioritize.

• DCS is Process-Oriented: A DCS is built to manage a continuous process where the relationship between variables is tightly coupled. If you change a temperature setpoint in a chemical reactor, it immediately affects the pressure and flow rate. The DCS is designed to handle these complex, high-speed interactions with “closed-loop” control.

• SCADA is Data-Oriented: SCADA is designed for supervisory oversight. Its primary job is to collect data from various remote sites and present it to an operator. It is “event-driven”—it waits for a sensor to report a change rather than constantly scanning every millisecond for micro-adjustments in a chemical reaction.

2. Geography: Localized vs. Distributed

Where is your equipment located? This is often the ultimate “decider.”

• Choose DCS if you are “Inside the Fence”: DCS is king for localized facilities like oil refineries, chemical plants, or pharmaceutical labs. Because it relies on high-speed Local Area Networks (LAN), it provides the near-instantaneous response times needed for complex machinery in a single footprint.

• Choose SCADA if you are “Across the Map”: If you are managing a 500-mile natural gas pipeline, a city-wide water distribution network, or a fleet of wind turbines, you need SCADA. SCADA is built to handle “unreliable” communication (cellular, satellite, or radio) across vast distances where a permanent high-speed cable isn’t feasible.

n and Scalability

• The DCS “Black Box”: A DCS is usually a proprietary “all-in-one” solution from a single vendor (like Honeywell, Emerson, or ABB). This makes it incredibly stable and easy to maintain because every part is designed to work together, but it can be very expensive to expand or change.

• The SCADA “LEGO Set”: SCADA is highly flexible. You can use a Schneider PLC, a Rockwell HMI, and a Siemens server all in the same system. This makes SCADA much cheaper to scale and easier to integrate with third-party software, but it requires more engineering effort to ensure everything talks to each other correctly.

5. The Verdict: Which one do you need?

You need a DCS if…

• You manage a continuous, high-hazard process (Refining, Nuclear, Power Gen).

• Your process requires thousands of I/O points in a single location.

• Downtime is not an option, and you need full hardware redundancy.

• The logic requires complex, multi-variable control (PID loops) that must interact in real-time.

You need SCADA if…

• Your assets are geographically dispersed (Utilities, Pipelines, Smart Cities).

• You need to monitor discrete manufacturing (Packaging, Automotive assembly).

• You want a cost-effective solution that can grow as you add new machines.

• Your focus is on data logging, analytics, and remote monitoring rather than millisecond-level process control.

Summary: The Hybrid Reality

In 2026, many facilities use both. A plant might use a DCS to control the hazardous chemical reaction at the core of the facility, while using a SCADA system to pull data from that DCS and combine it with data from the warehouse and shipping docks to provide a “single pane of glass” view for management.