In the world of industrial automation, SCADA (Supervisory Control and Data Acquisition) is the central nervous system of critical infrastructure. Whether it’s managing a city’s water supply, a massive power grid, or a high-speed manufacturing line, SCADA systems allow operators to monitor and control vast geographical areas from a single location.

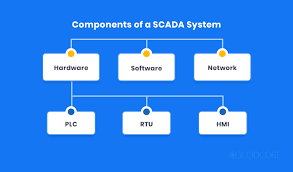

As we move deeper into the era of Industry 4.0, SCADA architecture has evolved from isolated, localized setups into highly integrated, data-driven ecosystems. Here are the five essential components that define a modern SCADA architecture.

1. Field Instrumentation and Control Devices

At the very bottom of the architecture—often referred to as Level 0 and Level 1—are the physical devices that interact with the industrial process.

-

Sensors and Actuators: Sensors measure physical parameters (temperature, pressure, flow), while actuators perform physical actions (opening a valve, starting a motor).

-

PLCs (Programmable Logic Controllers): These are the “workhorses” of the factory floor. They receive data from sensors and execute local logic to control the machinery in real-time.

-

RTUs (Remote Terminal Units): Unlike PLCs, RTUs are designed for wide-area communication. They are typically used in remote environments—like a pipeline in the middle of a desert—to transmit data back to the central station over wireless or satellite links.

2. The Communication Network (The Data Highway)

In a modern system, the communication network is the bridge between the field and the control room. Traditionally, this relied on proprietary serial cables, but modern SCADA has shifted toward Industrial Ethernet and wireless protocols.

-

Protocols: Modern systems use robust protocols like Modbus TCP, EtherNet/IP, and DNP3.

-

The Rise of MQTT: With the push toward the Industrial Internet of Things (IIoT), many SCADA architectures now utilize MQTT (Message Queuing Telemetry Transport), which is a “publish-subscribe” protocol that is much lighter and more efficient for remote data transmission.

-

Redundancy: High-availability networks often employ “ring topologies” to ensure that if one cable is cut, data can still reach its destination through an alternative path.

3. The MTU (Master Terminal Unit) or SCADA Server

The MTU is the brain of the entire operation. It is the central server that gathers data from the field devices, processes it, and stores it for analysis.

-

Data Acquisition: The server polls the PLCs and RTUs at set intervals to get the latest readings.

-

Alarming and Logic: The MTU is responsible for triggering alarms. If a pressure sensor reports a value above a safety threshold, the SCADA server recognizes this and notifies the operators immediately.

-

Historian: Most modern MTUs include a Data Historian, a specialized database optimized for time-series data. This allows engineers to look back at years of data to identify trends or investigate the cause of a past failure.

4. HMI (Human-Machine Interface)

The HMI is the “face” of the SCADA system. It is the software interface that translates complex machine data into visual graphics that a human operator can understand.

-

Visualization: Instead of looking at raw code or spreadsheets, operators see a digital twin of their plant. They can see a pump turn green when it’s running or red when it’s faulted.

-

Control: HMIs are bidirectional. An operator can click a button on a touchscreen to adjust a setpoint or shut down a turbine remotely.

-

Mobility: A defining feature of modern SCADA is the shift to Web-based HMIs (HTML5). This allows supervisors to monitor the plant from a tablet or smartphone anywhere in the world, rather than being tethered to a specific desktop in a control room.

5. Security and Integration Layer

In the past, SCADA systems were “air-gapped” (disconnected from the internet). Today, they are connected to corporate networks and the cloud, making Cybersecurity a core component of the architecture rather than an afterthought.

-

Firewalls and DMZs: Modern architecture uses a Demilitarized Zone (DMZ) to separate the sensitive industrial network (OT) from the corporate business network (IT).

-

Edge Computing: By processing some data at the “edge” (near the machine), companies can reduce latency and filter out “noise” before sending the most important data to the cloud.

-

ERP/MES Integration: Modern SCADA doesn’t live in a vacuum. It feeds data directly into Enterprise Resource Planning (ERP) systems to help management make better business decisions based on real-time production costs.

-

Summary: Why Architecture Matters

A well-designed SCADA architecture ensures that an industrial operation is not only efficient but also resilient. By choosing the right field devices, securing the communication network, and leveraging modern HMI tools, companies can transform their raw data into a competitive advantage.