What Does a Quality Score of 95% Mean in an OEE Context? (And Why It Matters)

Introduction

In the world of manufacturing, efficiency and productivity are measured by a powerful, all-encompassing metric: Overall Equipment Effectiveness (OEE). This score is not a single number but a product of three fundamental factors: Availability, Performance, and Quality.

While Availability measures how long your equipment is running, and Performance measures how fast it’s running, the Quality component gets straight to the heart of what your customers—and your bottom line—truly care about: producing good product.

So, what does it mean when your production line achieves a Quality score of 95%? It’s a fantastic achievement, but it also reveals a hidden cost that your team can work to eliminate.

Understanding the OEE Quality Component

The Quality component of OEE is the most straightforward factor to calculate, but arguably one of the most important for profitability.

The Formula: Good Parts vs. Total Parts

The Quality score is a ratio that measures how many of the products manufactured meet quality standards (the Good Count) compared to the Total Count of parts produced.

Important Note: The “Total Count” includes all products made, whether they are perfect, scrap, or require rework. The “Good Count” is typically defined as the number of units that successfully pass through the manufacturing process the first time without needing any rework. This is often referred to as the First Pass Yield (FPY).

What a 95% Quality Score Tells You

A Quality score of 95% means:

- For every 100 parts your machine produced, 95 of them were good parts (or “Right First Time”).

- The remaining 5 parts out of 100 (5%) were defective.

This 5% loss is known as your Quality Loss. This loss encompasses two main categories:

- Process Defects: Products that are scrapped or require rework due to issues during stable production (e.g., machine fault, incorrect material application).

- Reduced Yield: Defective parts produced at startup, such as those made while the machine is warming up, during testing, or immediately after a changeover.

The Hidden Impact of That 5% Loss

While a 95% score seems high—and in many industries, it’s considered a strong performance—it’s crucial to understand the compounding cost of that lost 5%.

1. Material and Capacity Waste

A defective part doesn’t just represent a loss of the final product; it represents wasted raw materials, energy, and most importantly, wasted capacity. Every minute spent producing a bad part is a minute that could have been used to produce a good, sellable part.

2. The Multiplier Effect on OEE

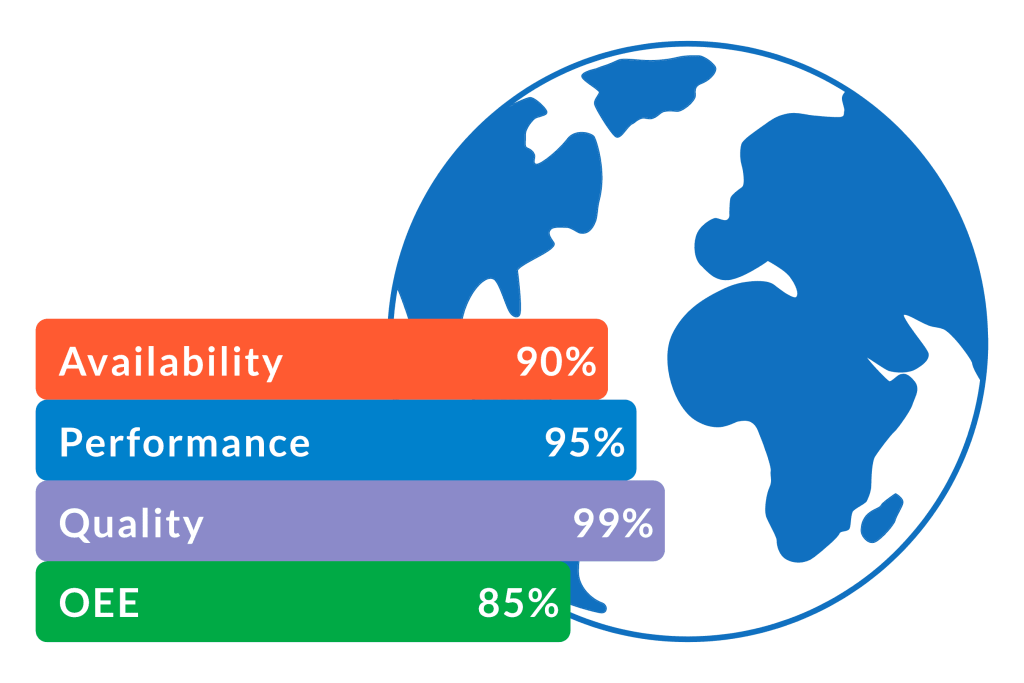

Remember, OEE is a multiplication of the three factors:

If your other scores are world-class (e.g., 90% Availability and 95% Performance), a 95% Quality score keeps your total OEE high:

However, compare this to a world-class Quality target of 99%:

The difference between 95% and 99% Quality translated to a 3.4-point gain in your overall OEE. That’s a significant jump in overall productivity from a small change in one metric.

How to Improve from 95% to World-Class (99%+)

In the OEE framework, a Quality score of 99% is often considered a “World-Class” target. Reaching this level requires a laser focus on your current 5% Quality Loss.

Here are three key strategies to target this loss:

1. Analyze Your Quality Loss Categories

Don’t just track the number of defects; track why they occurred.

- Defect Code Analysis: Implement a system to categorize every defect (e.g., ‘Scrap due to incorrect temperature,’ ‘Rework due to poor alignment,’ ‘Startup reject’). The Pareto Principle will quickly highlight the top 2-3 reasons for your 5% loss, giving you clear targets.

- Startup/Changeover Tracking: Separate defects that occur during the initial setup from those that happen during stable production. This helps you apply targeted fixes to your setup process (e.g., better standard operating procedures).

2. Implement Process Control Measures

Many defects are caused by process drift—small changes in temperature, pressure, or component feed.

- SOP Standardization: Ensure every operator follows the exact same start-up and running procedures to reduce human-error-related defects.

- Automated Monitoring: Use sensors and real-time data to automatically alert operators when a critical process parameter begins to drift before it leads to a defective part.

3. Focus on “Right First Time” (RFT)

The OEE definition of Quality is deliberately strict to encourage a culture of RFT.

- Eliminate Rework: Rework is a quality loss because it consumes productive time. Work to solve the root cause of rework so the part is made correctly the first time. If you count reworked parts as “Good,” your Quality score will be inflated and your OEE will mask a significant efficiency problem.

Conclusion

A 95% Quality score is a strong result, signaling that your process is mostly stable and your team is delivering high-quality products. It proves you have solid fundamentals.

However, in the relentless pursuit of manufacturing excellence, that remaining 5% is your most immediate opportunity for cost savings and productivity gains. By breaking down your Quality losses and systematically addressing the top reasons for scrap and rework, you can push that score closer to the 99% mark, turning waste into profit and truly achieving a World-Class OEE.