What is industrial automation and its benefits

Industrial Automation: Powering a Smarter, More Productive Future

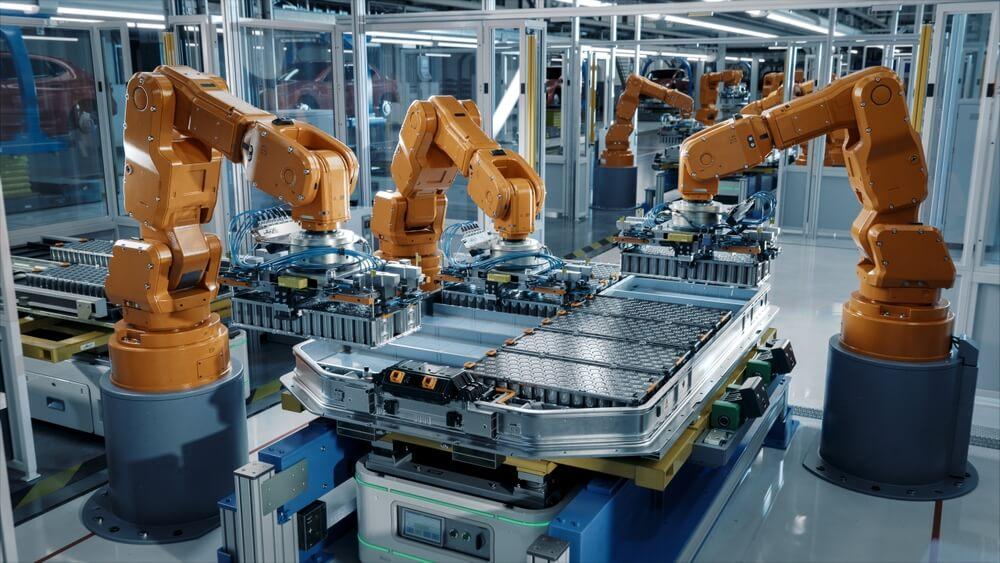

In today’s fast-paced world, the demand for efficiency, quality, and safety in manufacturing is higher than ever. To meet these challenges, industries are turning to a transformative technology: industrial automation. More than just robots on an assembly line, industrial automation is a complex system of hardware and software that is revolutionizing how we produce goods, from cars to consumer electronics. This technology is not just about replacing human labor; it’s about creating a more intelligent, agile, and productive manufacturing environment.What is Industrial Automation?

At its core, industrial automation involves using control systems, computers, and robotics to manage and operate machinery and processes in a factory or plant, minimizing the need for human intervention. The goal is to perform repetitive tasks, complex procedures, and hazardous operations with greater speed, accuracy, and reliability than is possible with manual labor. It is the backbone of modern manufacturing, ensuring consistent output and a seamless flow of production.

The Building Blocks of Automation

Industrial automation systems are not a single entity; they are a collection of interconnected components that work together to execute a task. Understanding these building blocks is key to grasping how automation functions.

- Sensors: These are the “eyes and ears” of the system. Sensors detect physical parameters such as temperature, pressure, light, and proximity. They gather real-time data from the factory floor and send it to the controller.

- Controllers (PLCs): The Programmable Logic Controller (PLC) is the brain of the automation system. It’s a rugged, specialized computer designed to handle industrial environments. The PLC receives input from sensors, processes the information based on a pre-programmed logic, and sends commands to the actuators.

- Actuators: These are the “muscles” of the system. Actuators are devices like electric motors, valves, and robotic arms that perform the physical work. They take the commands from the PLC and execute them, such as moving a product, opening a valve, or welding a part.

- Human-Machine Interface (HMI): This is the user interface that allows human operators to interact with the automation system. An HMI can be a simple panel or a sophisticated touchscreen display that provides real-time data, alarms, and controls for the machinery.

The Benefits of Industrial Automation

The adoption of industrial automation is driven by a powerful set of benefits that directly impact a company’s bottom line and overall operational excellence.

Increased Productivity and Efficiency

One of the most immediate benefits of automation is a significant boost in productivity. Automated systems can operate 24/7 without breaks or fatigue. They perform tasks at a consistent speed and can handle a much higher volume of work than human workers. This leads to faster production cycles, reduced lead times, and the ability to meet higher market demand.

Enhanced Quality and Consistency

Human error is a natural part of any manual process. However, automated systems execute tasks with a high degree of precision and repeatability. This consistency leads to a dramatic reduction in defects and waste. Each product is manufactured to the exact specifications every time, ensuring a uniform and high-quality final product. This not only enhances a brand’s reputation but also reduces the costs associated with quality control and product recalls.

Improved Safety

Industrial environments often involve dangerous tasks, such as handling heavy loads, working with hazardous materials, or operating at extreme temperatures. By automating these processes, companies can remove human workers from harm’s way. Robots and automated machinery can perform tasks in environments that are too dangerous for people, leading to a safer workplace and a substantial reduction in workplace injuries.

Reduced Operational Costs

While the initial investment in automation can be substantial, the long-term cost savings are significant. Automation reduces labor costs and minimizes waste from errors. It also improves energy efficiency and can lead to lower insurance premiums due to a safer working environment. Over time, these savings lead to a strong return on investment (ROI).

Types of Industrial Automation

Industrial automation is not a one-size-fits-all solution. It can be categorized into three main types based on its flexibility and application.

- Fixed Automation: This type is used for high-volume production of a single product. The machinery is specifically designed for a single task and is very difficult to reconfigure. Think of an automobile assembly line that repeatedly performs the same task on every car that passes by.

- Programmable Automation: This is more flexible. The equipment can be reprogrammed to handle different product configurations or change the sequence of operations. It is suitable for batch production, where different product runs are required. For example, a robotic arm can be reprogrammed to weld different car models.

- Flexible Automation: The most advanced type, flexible automation, allows for quick and easy changes to the production system without losing significant time. This is ideal for manufacturing multiple product variations simultaneously and is central to the concept of mass customization.

The Future of Automation (Industry 4.0)

The next wave of industrial automation, often called Industry 4.0, is bringing together automation with other advanced technologies like the Internet of Things (IoT), Artificial Intelligence (AI), and cloud computing. The goal is to create “smart factories” where machines communicate with each other and with a central control system. AI can optimize production schedules and predict equipment failures before they happen, while IoT sensors provide an unprecedented amount of data for analysis, leading to even greater efficiency and productivity.

In conclusion, industrial automation is no longer a luxury but a necessity for companies seeking to remain competitive in the global market. By embracing this technology, businesses can achieve higher levels of productivity, safety, and quality, paving the way for a more intelligent and prosperous industrial future.