A Distributed Control System (DCS) is a control system used in process industries like oil and gas, chemicals, and pharmaceuticals. It’s designed to manage and control complex, continuous processes across a large geographic area. Unlike a single, central controller, a DCS uses a network of distributed controllers to monitor and control various parts of a plant. This distributed architecture offers several advantages, including improved reliability, scalability, and flexibility.

What Is a DCS and How Does It Work?

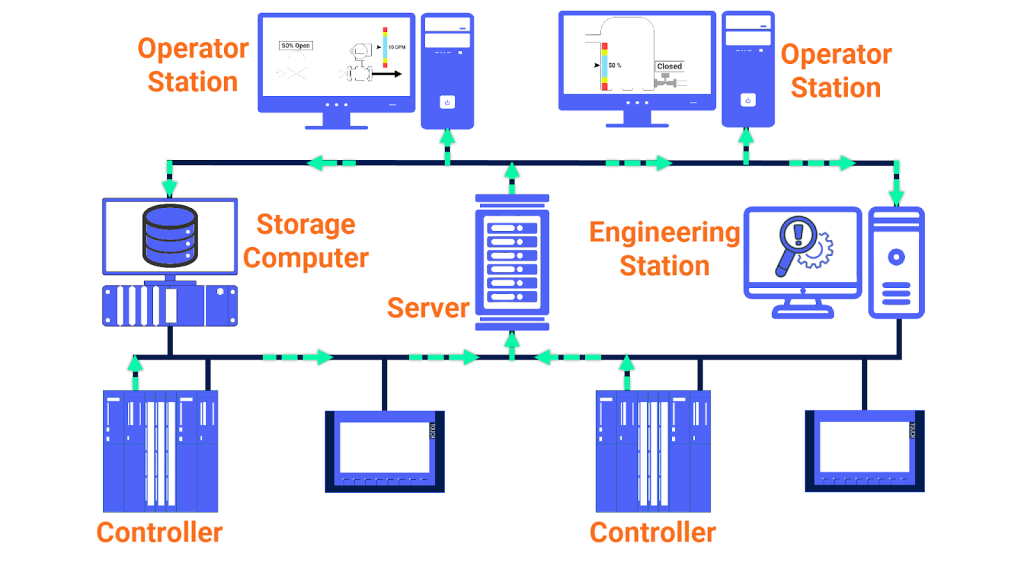

A DCS is essentially a computer-based system that automates the control of industrial processes. The system’s core is its distributed nature. Instead of having one massive central processing unit (CPU) running everything, a DCS uses multiple smaller controllers located closer to the equipment they manage. These controllers, also known as field controllers or Local Control Units (LCUs), are connected to a central operator station via a high-speed communication network. This setup allows for parallel processing, where different parts of the plant can be controlled simultaneously and independently.

The main components of a typical DCS include:

- Engineering Station: This is where engineers configure, program, and maintain the entire DCS. They create the control logic, define the parameters, and set up the human-machine interface (HMI).

- Operator Station: This is the control room interface where operators monitor the process, view alarms, and manually adjust control parameters if needed. The operator station provides a comprehensive view of the plant’s status in real-time.

- Field Control Stations (FCS): These are the intelligent controllers located near the process equipment. They directly communicate with field devices like sensors, valves, and motors. They execute the control logic and collect data from the field.

- Communication Network: This is the backbone of the DCS, connecting all the stations and controllers. It’s a reliable, redundant network designed to ensure uninterrupted communication.

The distributed architecture means that if one controller fails, only the portion of the plant it controls is affected. The rest of the system continues to operate normally, a significant improvement in system reliability compared to centralized systems.

Why Is a DCS Needed in Automation?

DCS technology is critical for industries with complex, continuous processes. Imagine a chemical plant that needs to maintain precise temperatures, pressures, and flow rates across dozens of reactors and tanks simultaneously. A simple Programmable Logic Controller (PLC) might not be up to the task due to the sheer number of I/O points and the complexity of the control loops. A DCS, however, is built for this scale and complexity.

Key reasons why a DCS is essential:

- Enhanced Reliability and Redundancy: The distributed nature of a DCS means it’s inherently more reliable. Critical components can be configured with redundancy, ensuring that the system can continue to operate even if a hardware component fails. This is crucial for safety and minimizing downtime.

- Scalability: A DCS can be easily expanded to accommodate new equipment or processes. You can add more controllers to the network without a major overhaul of the existing system.

- Advanced Control Capabilities: A DCS offers sophisticated control algorithms and advanced process control (APC) features that are not typically available in simpler systems. This allows for better process optimization, improved product quality, and reduced energy consumption.

- Centralized Monitoring and Control: While the control is distributed, the operator has a centralized view of the entire plant. The HMI provides a unified interface for monitoring, alarming, and controlling all processes.

- Integrated Safety Systems: Many modern DCS solutions are integrated with safety instrumented systems (SIS), providing a unified platform for both process control and safety, simplifying engineering and maintenance.

Solutions in DCS Automation

Implementing a DCS is a significant investment, but modern solutions are making it more accessible and powerful than ever. The focus today is on integration, data analytics, and user experience.

- Integration with Enterprise Systems: Modern DCS solutions are designed to integrate seamlessly with higher-level enterprise systems, such as Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP). This creates a connected plant floor, enabling real-time data exchange and better business decisions.

- Data Analytics and IIoT: The rise of the Industrial Internet of Things (IIoT) has led to DCS solutions that can handle vast amounts of data from field devices. These systems can analyze this data to predict equipment failures, optimize processes, and identify opportunities for improvement. Predictive maintenance is a key benefit, allowing companies to schedule maintenance proactively rather than reactively.

- Virtualization and Cloud Computing: Many DCS vendors now offer solutions that can be run on virtualized servers or even in the cloud. This reduces hardware costs, simplifies maintenance, and allows for easier system upgrades. It also enables remote monitoring and control, which is particularly useful for geographically dispersed operations.

- Human-Machine Interface (HMI) Advancements: The HMIs of modern DCS systems are highly intuitive and user-friendly. They use advanced graphics, dashboards, and alarm management tools to provide operators with a clear, concise view of the process. This helps them make faster, more informed decisions, especially during critical events.

In conclusion, a DCS is a powerful automation tool for managing complex industrial processes. Its distributed architecture provides unparalleled reliability and scalability, while modern solutions are leveraging new technologies like IIoT and cloud computing to create smarter, more connected, and more efficient industrial plants.